- Joined

- Dec 20, 2012

- Messages

- 16

Hi all,

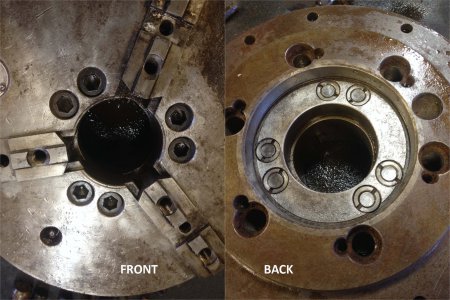

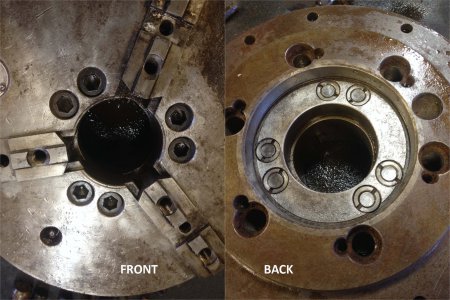

I have been tearing down an old cushman 12" lathe chuck and 6 bolts don't want to budge (even with my trusty impact gun). They appear to go thru with a funky looking back - that may be a nut? Any ideas? What type of driver would I use? I'm being gentle and want to avoid the "bigger hammer" method of disassembly. Here's a pic.

I have been tearing down an old cushman 12" lathe chuck and 6 bolts don't want to budge (even with my trusty impact gun). They appear to go thru with a funky looking back - that may be a nut? Any ideas? What type of driver would I use? I'm being gentle and want to avoid the "bigger hammer" method of disassembly. Here's a pic.