- Joined

- Jan 25, 2015

- Messages

- 2,558

Is there any real functional difference between a 3/4 hp DC motor and a 3/4 HP AC motor?

I know the arguments for and against each (speed control, cost, vfd, maintenance, etc).

What I am wondering is if a lathe powered by a 3/4 hp DC motor will function any differently than one powered by a 3/4 HP AC motor.

For the sake of argument, lets say the DC motor is controlled by the latest up to date speed controller and the AC motor by the latest VFD.

Reason I ask is I've been reading conflicting info on DC motors being harder on lathes (IE: higher startup torque) than a comparable AC motor.

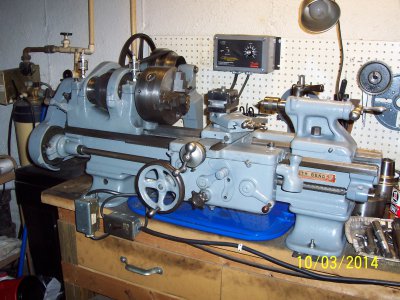

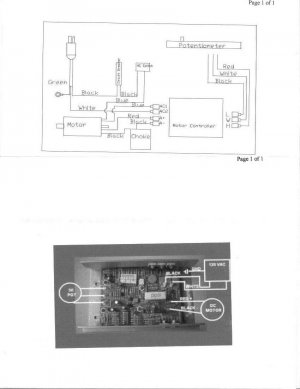

I'm going DC on my Atlas TH42 (probably with a Baldor 3440 3/4 HP run by my Cycletrol 150), I just don't want to be unpleasantly surprised by "breakage".

I'm thinking it shouldn't be a problem since the Atlas is factory rated (max, IIRC) for a 1/2 HP AC motor.

Besides the fact that I have somewhat of a preference for DC, the controller was inexpensive (40 bucks for the cycletrol and I have another in the drawer for spares) and the Baldor motor looks like it will be around 100 bucks plus 50 odd dollars to ship it.

So, around 200-250 bucks and I'll have a variable speed 3/4 HP drive with Jog/Stop/Brake/Rev vice my current single phase 1/8 HP AC drive.

So, any difference in 3/4 HP DC or 3/4 HP AC I should be concerned about?

I know the arguments for and against each (speed control, cost, vfd, maintenance, etc).

What I am wondering is if a lathe powered by a 3/4 hp DC motor will function any differently than one powered by a 3/4 HP AC motor.

For the sake of argument, lets say the DC motor is controlled by the latest up to date speed controller and the AC motor by the latest VFD.

Reason I ask is I've been reading conflicting info on DC motors being harder on lathes (IE: higher startup torque) than a comparable AC motor.

I'm going DC on my Atlas TH42 (probably with a Baldor 3440 3/4 HP run by my Cycletrol 150), I just don't want to be unpleasantly surprised by "breakage".

I'm thinking it shouldn't be a problem since the Atlas is factory rated (max, IIRC) for a 1/2 HP AC motor.

Besides the fact that I have somewhat of a preference for DC, the controller was inexpensive (40 bucks for the cycletrol and I have another in the drawer for spares) and the Baldor motor looks like it will be around 100 bucks plus 50 odd dollars to ship it.

So, around 200-250 bucks and I'll have a variable speed 3/4 HP drive with Jog/Stop/Brake/Rev vice my current single phase 1/8 HP AC drive.

So, any difference in 3/4 HP DC or 3/4 HP AC I should be concerned about?

Last edited: