- Joined

- Jan 14, 2012

- Messages

- 56

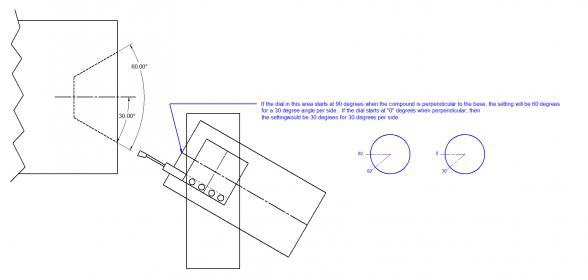

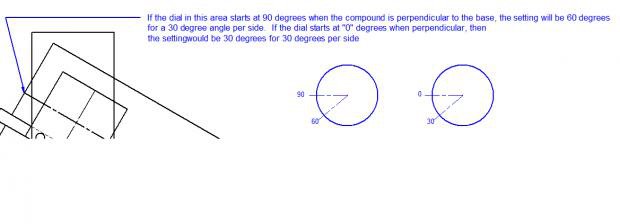

Quick question on tapers:

I was just messing around this morning with the compound on my mini-lathe by cutting some internal tapers on a small left over piece. If I want to cut a 60º taper, at what angle do I set my compound? Thanks.

I was just messing around this morning with the compound on my mini-lathe by cutting some internal tapers on a small left over piece. If I want to cut a 60º taper, at what angle do I set my compound? Thanks.