Hey Folks

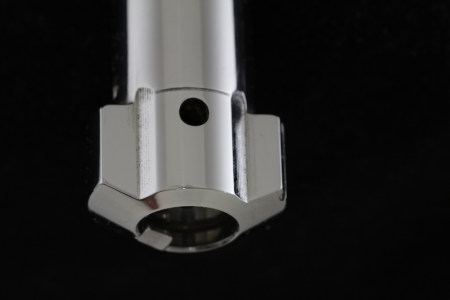

I am working on practice barrels for a Bat B action. The breech cone/barrel angle is 25*. None of my tools/holders allow me to reach in far enough to cut the angle before the heal of the tool holder rubs on the the barrel. I have ground a couple of HHS tool bits with out much success. They cut, but not smoothly or leave a smooth surface. I have tried different spindle speeds. Anyone offer some ideas/pics on the correct or best geometry for a hhs tool to cut this angle?

Thanks

Bob

I am working on practice barrels for a Bat B action. The breech cone/barrel angle is 25*. None of my tools/holders allow me to reach in far enough to cut the angle before the heal of the tool holder rubs on the the barrel. I have ground a couple of HHS tool bits with out much success. They cut, but not smoothly or leave a smooth surface. I have tried different spindle speeds. Anyone offer some ideas/pics on the correct or best geometry for a hhs tool to cut this angle?

Thanks

Bob