- Joined

- Jul 4, 2014

- Messages

- 156

Guys

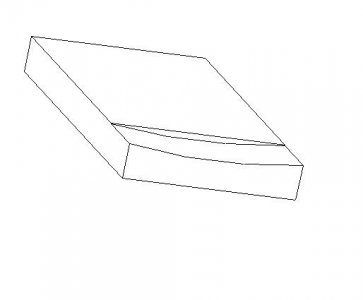

I need advice. I want to cut 14 inch diameter curvature on 2 inch wide aluminum pieces as below. I made a sketch as attached below.

My Grizzly G4000 lathe is a 9x19 and can not be used to turn 14 inch diameter. That leaves me only my mini-mill to do this machining. It is not a CNC and I calculated the x-y movements for the cutter in small steps. The process is moving the milling cutter manually in X-Y steps as if it is a CNC process. Steps are roughly 0.0315" in X axis. On Y axis the cutter is moved in much smaller steps to follow the radius desired. I tried milling it using a 3/4 inch end mill. The result is as attached below.

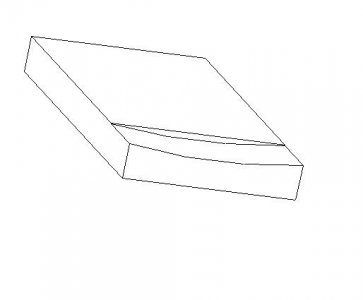

The above image is what I made. You may notice curved surface has small steps but that is OK. It is the process involved that makes it tedious. I wish there is an easier way. I do not own a rotary stage and do not plan on buying one either.

Any ideas?

Thanks

Prasad

Eastern PA

I need advice. I want to cut 14 inch diameter curvature on 2 inch wide aluminum pieces as below. I made a sketch as attached below.

My Grizzly G4000 lathe is a 9x19 and can not be used to turn 14 inch diameter. That leaves me only my mini-mill to do this machining. It is not a CNC and I calculated the x-y movements for the cutter in small steps. The process is moving the milling cutter manually in X-Y steps as if it is a CNC process. Steps are roughly 0.0315" in X axis. On Y axis the cutter is moved in much smaller steps to follow the radius desired. I tried milling it using a 3/4 inch end mill. The result is as attached below.

The above image is what I made. You may notice curved surface has small steps but that is OK. It is the process involved that makes it tedious. I wish there is an easier way. I do not own a rotary stage and do not plan on buying one either.

Any ideas?

Thanks

Prasad

Eastern PA

Last edited:

That is not easy to do by hand.

That is not easy to do by hand.