- Joined

- Jul 26, 2013

- Messages

- 584

I'm back with just a little update...

I haven't had much time to devote to the shop over the weekend, so I snuck away from work that I should be doing, to get a bit more done. I decided to finish cleaning up the swivel, before moving on to the saddle. Starting with the oilers, I had to remove four allen cap-screws holding each oiler to the swivel. These capscrews were imbedded with old chips and took some cleaning before they could be removed. I then carefully tapped on the oilers to release them, keeping the gasket intact. I will attempt to make a cover to replace the missing one....

Each oiler has two holes leading to the bearing/nut/feed gear assemblies, lubricating each side seperately. One oiler has a third hole which feeds both the front and back ways for table contact. Cleaning the oiling passages was fairly straightforward, first using pipe cleaners and mineral spirits, then squirting mineral spirits down through them, and finally using compressed air to blow them out. * Note to self * .... When applying compressed air to oiling passageways, place a cloth over the exit hole to avoid a muddy spray pattern on the walls and ceiling...

At the rear of the swivel, between the oilers, is further evidence of the mill's original dark blue color. It's one of the very few areas that the re-painter missed...

I then went on to clean out the two oiling passageways that feed the bottom of the swivel from two zerk fittings at the front. These were liberally greased and took a bit more effort to clean them. Next, I began to clean up the saddle while still in position. By the shadow of the swivel on the saddle, it looks like this mill spent much of it's life with the table at 45* ...

Next comes the removal of the saddle.... this will be far more complicated than the work done so far. For starters, I can't figure out how to get the camlock mechanism off of the handwheel spindle, in order to remove the handwheel. The handwheel must come off before the saddle can slide forward. It was suggetsed to me, that I should try to remove the handwheel and feedscrew all at once.

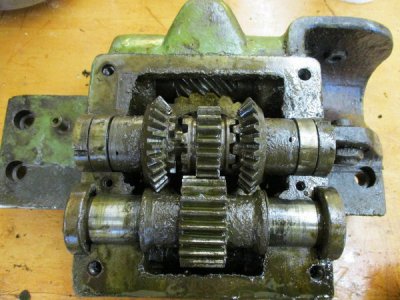

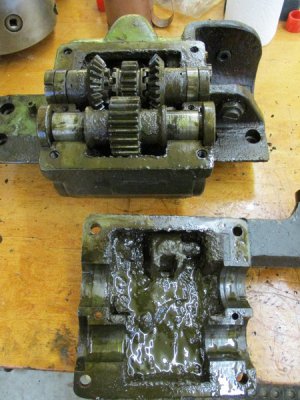

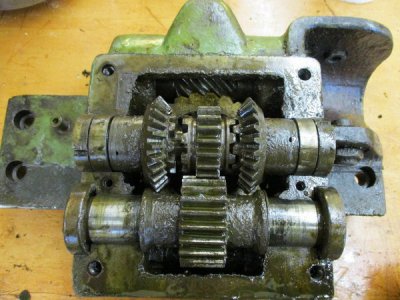

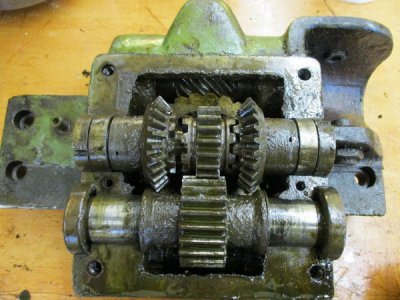

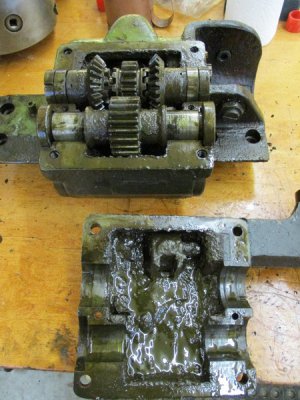

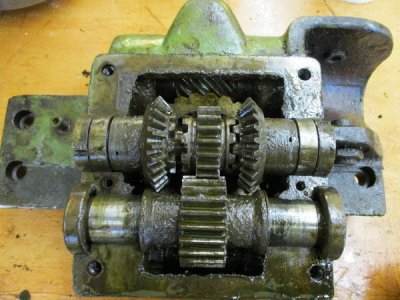

There is also the gearbox and central gearing to attend to... One part at a time...

Brian

I haven't had much time to devote to the shop over the weekend, so I snuck away from work that I should be doing, to get a bit more done. I decided to finish cleaning up the swivel, before moving on to the saddle. Starting with the oilers, I had to remove four allen cap-screws holding each oiler to the swivel. These capscrews were imbedded with old chips and took some cleaning before they could be removed. I then carefully tapped on the oilers to release them, keeping the gasket intact. I will attempt to make a cover to replace the missing one....

Each oiler has two holes leading to the bearing/nut/feed gear assemblies, lubricating each side seperately. One oiler has a third hole which feeds both the front and back ways for table contact. Cleaning the oiling passages was fairly straightforward, first using pipe cleaners and mineral spirits, then squirting mineral spirits down through them, and finally using compressed air to blow them out. * Note to self * .... When applying compressed air to oiling passageways, place a cloth over the exit hole to avoid a muddy spray pattern on the walls and ceiling...

At the rear of the swivel, between the oilers, is further evidence of the mill's original dark blue color. It's one of the very few areas that the re-painter missed...

I then went on to clean out the two oiling passageways that feed the bottom of the swivel from two zerk fittings at the front. These were liberally greased and took a bit more effort to clean them. Next, I began to clean up the saddle while still in position. By the shadow of the swivel on the saddle, it looks like this mill spent much of it's life with the table at 45* ...

Next comes the removal of the saddle.... this will be far more complicated than the work done so far. For starters, I can't figure out how to get the camlock mechanism off of the handwheel spindle, in order to remove the handwheel. The handwheel must come off before the saddle can slide forward. It was suggetsed to me, that I should try to remove the handwheel and feedscrew all at once.

There is also the gearbox and central gearing to attend to... One part at a time...

Brian