- Joined

- Feb 20, 2023

- Messages

- 20

Hi All

After getting my cheap Chinese mini lathe fixed, I had lots of ideas but eventually just fixed the controller board on it, I am looking at doing my first real project on it.

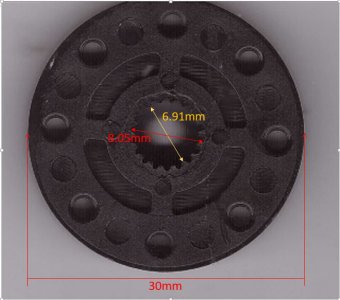

I am into robotics so use a lot of servos and what I want to be able to do is make custom servo horns to suit my designs, I can do basic milling by putting a milling bit in the lathe chuck then use the compound table to hold the piece and do basic milling that way, but what I have no idea about is how to create the internal gear that mates with the servo gear, this also has to be a tight fit unlike gear to gear where play is need for movement., the internal gear is also very small around 8mm in diameter.

Now I know the basics, drill a hole to the diameter of the peak of the gear, then use a means to broach.

Looking for advice on the best way to do this.

Cheers

DJ

After getting my cheap Chinese mini lathe fixed, I had lots of ideas but eventually just fixed the controller board on it, I am looking at doing my first real project on it.

I am into robotics so use a lot of servos and what I want to be able to do is make custom servo horns to suit my designs, I can do basic milling by putting a milling bit in the lathe chuck then use the compound table to hold the piece and do basic milling that way, but what I have no idea about is how to create the internal gear that mates with the servo gear, this also has to be a tight fit unlike gear to gear where play is need for movement., the internal gear is also very small around 8mm in diameter.

Now I know the basics, drill a hole to the diameter of the peak of the gear, then use a means to broach.

Looking for advice on the best way to do this.

Cheers

DJ