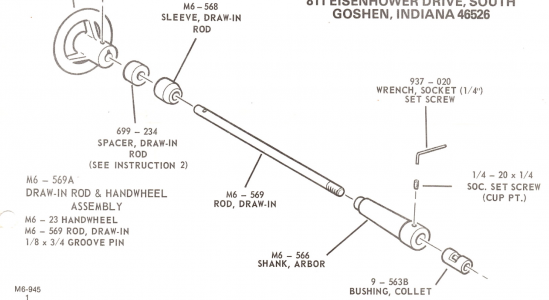

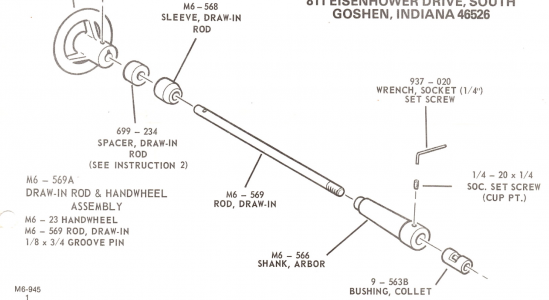

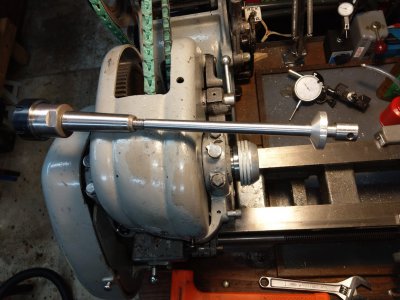

I have some end mills that I would like to use with the Craftsman 6in 101 lathe. I'm missing the arbor shank and brushing collet from the diagram below. I'm not sure how this works. Is this the best setup for end mill work on the 6in lathe or should I be looking for some other attachments so that I can run this lathe as an end mill?