- Joined

- Mar 21, 2018

- Messages

- 1,598

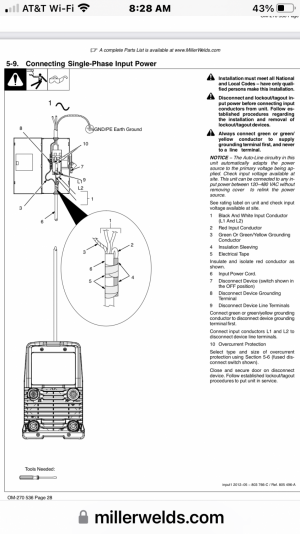

My understanding is that NEC applies to wiring to the socket, beyond the socket (i.e plug/cordage it is UL). NEC does have specifications for color coding as you have noted and also specific to socket/plug ratings for different applications, but with UL you can get away with different color codes and smaller gauge wire then would be allowed under NEC.

That makes sense. However, I try to follow color schemes even when I wire plugs, just because it is easier to indicate which wires do what. I'm perplexed as to why you would not use the red wire over the white wire for the second LINE wire when it is available.