-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

COLCHESTER CHIPMASTER

- Thread starter ARM

- Start date

- Joined

- Nov 3, 2013

- Messages

- 405

According to the lathes.uk site the spindle is bored to take a MT4 taper but was fitted with a hardened sleeve to take it to MT2.

http://www.lathes.co.uk/chipmaster/

http://www.lathes.co.uk/chipmaster/

According to the lathes.uk site the spindle is bored to take a MT4 taper but was fitted with a hardened sleeve to take it to MT2.

http://www.lathes.co.uk/chipmaster/

Hi Senna

We had already checked that.

Ours is one of the few last ones to leave the production line.

The Seller has just confirmed it is larger than MT 4

So it will definitely be a MT 4.5 !!!

thanks all the same.

aRM

Well, Tony of lathes.co.uk must've written that MT4 -> MT2 after a visit to the pub!

The Chipmaster has a MT4½, and with it was delivered a short sleeve,

with MT3 inside. Which matches the tailstock.

Anyone, who has seen the sales prospect or the manual knows this.

Cheers

Erik

PS: Arm - have you thought about the collets?

Hello there ERIK

Glad to see U active here as well.

Heck man this is a small world indeed. Thought all along that U were based in the UK !!??

At this point in time I really don't know what to do with this piece of sh.t that I was stung with. (Forgive the expletives, I got no decent words left ~!@#$%^&*()_ ) This was the real GATSBY !!

There's so much wrong with it that I don't think I want to spend another bloody cent on it. It's just going to be a too costly. Think about it.

The VARIATOR seems like its going.

The MATRIX CLUTCH is also on its way out.

The longitudinal FEED WHEEL has to be replaced. There's no readings on it.

We have to get a 5" BACK PLATE to mount the CHUCK, there's none at present. Can't do any work at all !!!

The rear SPLASH GUARD is missing, never mind the CHUCK GUARD.

And the biggest disaster, there's a huge ding on the right side of the BED just before the CHUCK, where most our work is going to be done, which will require complete re-GRINDING of the BED.

Not to mention numerous bolts and Nuts on the Hand wheel Mountings which look really worn, if not damaged.

With the way we feel at present, we just can't wait to dump this piece of crap out the workshop.

Our new machine should be arriving soon, IA, so this will definitely get thrown out, RUST to ROT, definitely not to be caught by another unwitting Buyer.

Sorry to hang our snakes on U, we will abstain for now.

As a matter of interest, our new Machine has a MT 5 SPINDLE BORE for which we have already bought a Complete 5C COLLET LATHE ADAPTOR, including the DRAW TUBE and the HAND WHEEL to go with, from down under - OZ LAND, of all places !!! Have Family there who will bring these items early next month.

So we will finally get to use all our 5C COLLETS, LORD WILLING.

Thanks all the same. We appreciate the exclusive Offer. Those are precision COLLETS indeed.

LORD BLESS

aRM

- Joined

- Nov 21, 2012

- Messages

- 793

G'day ARM,

sorry to hear that you were stuck with a lemon. The ding in the bed may be able to be stoned out. Dings are nowhere near as bad as wear over a longer section of the bed.

Also, the variator may come to life if you use the correct oil. It's rare that they are thrashed over the whole speed range. It's usually a problem in one "band" as the wrong oil was likely used and a groove is worn in the contact surface. Failing this, you can change it to VFD easily and this will eliminate the need for the variator.

The matrix clutch probably just needs to be adjusted. These do wear but I have never heard of one being worn out.

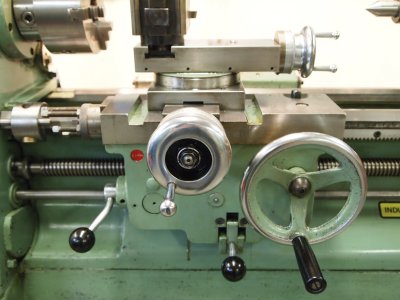

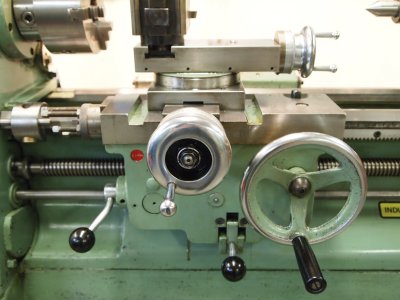

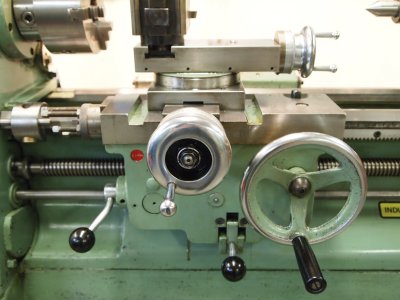

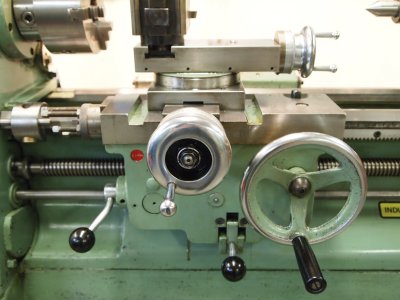

When you say longitudinal feed wheel, which are you referring to in the picture below?

The chuck unfortunately is a d1-3 camlock which can be quite expensive but you can find cheaper alternatives. It's just that the Far East variants are not rated for 3000 rpm so if you use a VFD, you will have to limit the motor to the chuck's max rpm.

As for the splash and chuck guards, these rarely follow the machine. I was lucky to get my machine as complete and in as good condition as it is. I have more info here if you are interested:

http://wanderingaxeman.blogspot.no/search/label/Garage

I hope you manage to iron out the kinks. I want everyone to be happy with their Chippies as I have been very pleased with mine.

Paul.

sorry to hear that you were stuck with a lemon. The ding in the bed may be able to be stoned out. Dings are nowhere near as bad as wear over a longer section of the bed.

Also, the variator may come to life if you use the correct oil. It's rare that they are thrashed over the whole speed range. It's usually a problem in one "band" as the wrong oil was likely used and a groove is worn in the contact surface. Failing this, you can change it to VFD easily and this will eliminate the need for the variator.

The matrix clutch probably just needs to be adjusted. These do wear but I have never heard of one being worn out.

When you say longitudinal feed wheel, which are you referring to in the picture below?

The chuck unfortunately is a d1-3 camlock which can be quite expensive but you can find cheaper alternatives. It's just that the Far East variants are not rated for 3000 rpm so if you use a VFD, you will have to limit the motor to the chuck's max rpm.

As for the splash and chuck guards, these rarely follow the machine. I was lucky to get my machine as complete and in as good condition as it is. I have more info here if you are interested:

http://wanderingaxeman.blogspot.no/search/label/Garage

I hope you manage to iron out the kinks. I want everyone to be happy with their Chippies as I have been very pleased with mine.

Paul.

Hello PAUL

At the outset let me say THANKS for the response.

Have already eyeballed the review of Your Chippy a couple of weeks ago. We were left marvelled. That is indeed a thing of beauty, U lucky Man.

The problem with us is we are neither trained machinists, nor Technically trained nor do we have an aptitude to strip this beast and get her back in shape. Period.

Been a blue collar worker ( pen pusher ) my whole life and have only recently learnt to use my Lathe as a Hobbyist.

To answer some of Your comments and questions...............

U are right, that ding can be stoned out carefully.

The Seller did say that he got advise from U on adjusting the MATRIX CLUTCH, but he battled to get it right when he started the machine for demo.

The VARIATOR is working, albeit rather noisily. Have also had others say the easiest way to go would be via the VFD. That will include changing the motor as well.

The biggest wheel on the extreme Right of the Apron that feeds longitudinally - is not this one supposed to have the readings like the CROSS SLIDE WHEEL ???

Had a supposedly good friend (more likely Fiend ) suggest a DRO to compensate for that.

The seller did give us a 5" ROHM 4 JAW (SELF-CENTERING) CHUCK with the machine, but no BACK PLATE.

We checked already, CDCO in the States has cheap 5" D1-3 Backplates which will mount this CHUCK. Bison, which are also good, 3 Jaw chucks could be had as well.

What next !!!

Seems like there will just be no limit to what this beast will require to really function at optimum.

And it will require a proper spray paint job to make her look decent.

Really need to decide which way to go here.

Kindest regards

aRM

At the outset let me say THANKS for the response.

Have already eyeballed the review of Your Chippy a couple of weeks ago. We were left marvelled. That is indeed a thing of beauty, U lucky Man.

The problem with us is we are neither trained machinists, nor Technically trained nor do we have an aptitude to strip this beast and get her back in shape. Period.

Been a blue collar worker ( pen pusher ) my whole life and have only recently learnt to use my Lathe as a Hobbyist.

To answer some of Your comments and questions...............

U are right, that ding can be stoned out carefully.

The Seller did say that he got advise from U on adjusting the MATRIX CLUTCH, but he battled to get it right when he started the machine for demo.

The VARIATOR is working, albeit rather noisily. Have also had others say the easiest way to go would be via the VFD. That will include changing the motor as well.

The biggest wheel on the extreme Right of the Apron that feeds longitudinally - is not this one supposed to have the readings like the CROSS SLIDE WHEEL ???

Had a supposedly good friend (more likely Fiend ) suggest a DRO to compensate for that.

The seller did give us a 5" ROHM 4 JAW (SELF-CENTERING) CHUCK with the machine, but no BACK PLATE.

We checked already, CDCO in the States has cheap 5" D1-3 Backplates which will mount this CHUCK. Bison, which are also good, 3 Jaw chucks could be had as well.

What next !!!

Seems like there will just be no limit to what this beast will require to really function at optimum.

And it will require a proper spray paint job to make her look decent.

Really need to decide which way to go here.

Kindest regards

aRM

- Joined

- Aug 5, 2013

- Messages

- 260

so sorry to hear of the issues, but perhaps they can be worked out.

Some good folks here to give you advise.

There is also possibility to part it out if you felt machine beyond repair.

Sometimes the parts are worth more than the machine in whole.

We'd like to see pictures!

Take cheer.. one step at a time

Dan

Some good folks here to give you advise.

There is also possibility to part it out if you felt machine beyond repair.

Sometimes the parts are worth more than the machine in whole.

We'd like to see pictures!

Take cheer.. one step at a time

Dan

Hello PAUL

At the outset let me say THANKS for the response.

Have already eyeballed the review of Your Chippy a couple of weeks ago. We were left marvelled. That is indeed a thing of beauty, U lucky Man.

The problem with us is we are neither trained machinists, nor Technically trained nor do we have an aptitude to strip this beast and get her back in shape. Period.

Been a blue collar worker ( pen pusher ) my whole life and have only recently learnt to use my Lathe as a Hobbyist.

To answer some of Your comments and questions...............

U are right, that ding can be stoned out carefully.

The Seller did say that he got advise from U on adjusting the MATRIX CLUTCH, but he battled to get it right when he started the machine for demo.

The VARIATOR is working, albeit rather noisily. Have also had others say the easiest way to go would be via the VFD. That will include changing the motor as well.

The biggest wheel on the extreme Right of the Apron that feeds longitudinally - is not this one supposed to have the readings like the CROSS SLIDE WHEEL ???

Had a supposedly good friend (more likely Fiend ) suggest a DRO to compensate for that.

The seller did give us a 5" ROHM 4 JAW (SELF-CENTERING) CHUCK with the machine, but no BACK PLATE.

We checked already, CDCO in the States has cheap 5" D1-3 Backplates which will mount this CHUCK. Bison, which are also good, 3 Jaw chucks could be had as well.

What next !!!

Seems like there will just be no limit to what this beast will require to really function at optimum.

And it will require a proper spray paint job to make her look decent.

Really need to decide which way to go here.

Kindest regards

aRM

- Joined

- Aug 5, 2013

- Messages

- 260

Looks like a pretty clean machine to me.

I cant see the ding in the way you mentioned, or is it a spot just in front of the chuck on the flat way?

If so, that's where the tailstock would ride, which unlikely would be an issue..

Also you don't need markings on carriage feed wheel, never use those.. too coarse..

Likely never had.

Important ones are on cross feed and compound

I cant see the ding in the way you mentioned, or is it a spot just in front of the chuck on the flat way?

If so, that's where the tailstock would ride, which unlikely would be an issue..

Also you don't need markings on carriage feed wheel, never use those.. too coarse..

Likely never had.

Important ones are on cross feed and compound

Last edited: