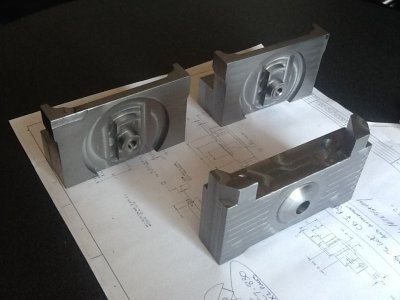

I will try, but it will be a few days at the least. My machine is down while I make some enhancements (replacing variable speed drive in the head and adding spindle encoder). I had a trial run last night, but need to make some adjustments. Close now though. I ran this program in "simulation" mode.

Any hints on real the assignment? Maybe I'm missing something, but I don't understand how to create the gradually increasing arc without cheating and using controller specific features.

Any hints on real the assignment? Maybe I'm missing something, but I don't understand how to create the gradually increasing arc without cheating and using controller specific features.