- Joined

- May 7, 2014

- Messages

- 776

Hi everyone. Hope and trust everyone has been well and prospering! My new job has been keep me way to busy, but that's life. Good to see the threads here in CNC land.

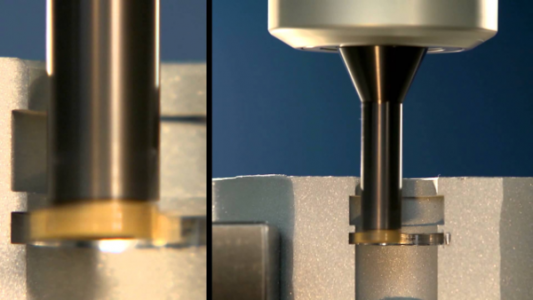

Q: On the hobby front, I am making a part for my Plasma gear. I would like to use a spring-steel ring clip down in a 1.17" hole that is .21 deep. It will hold in a disk magnet. I want to be able to replace them as needed.

What type of cutter would you use for that? it's Alu-6061. CAMis Fusion360, I will need to figure out the CAM setup too... (if anyone knows that as well?).

Peace and best to all.

Jeff

Q: On the hobby front, I am making a part for my Plasma gear. I would like to use a spring-steel ring clip down in a 1.17" hole that is .21 deep. It will hold in a disk magnet. I want to be able to replace them as needed.

What type of cutter would you use for that? it's Alu-6061. CAMis Fusion360, I will need to figure out the CAM setup too... (if anyone knows that as well?).

Peace and best to all.

Jeff