- Joined

- Feb 24, 2019

- Messages

- 927

Today I was making some clamps for the bed of my CNC Project.

I started all the threads on the mill and then finished them in the comfort of my living room using a power drill.

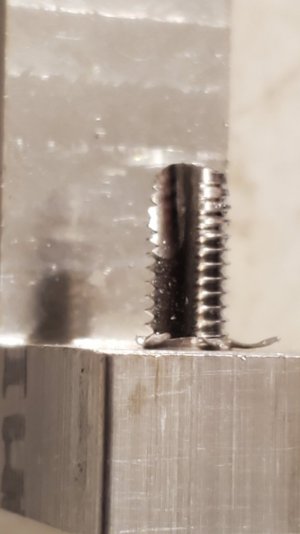

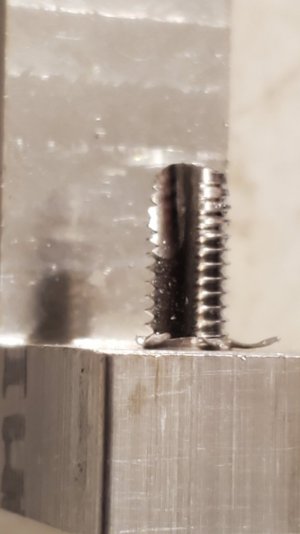

The tap is one that pushes the chips down and out. The thickness I'm tapping is about 3/4" Using M6X1 threads.

Well, I know better and did it anyhow, but I was tapping dry. On one of the pieces I got a chunk of aluminum stuck in the cutter on the back side of the piece. I've tried clearing it with all kinds of "digging it out" methods and it won't budge. Luckily I have a few of these taps so I was able to finish the rest but I'd like to free this tap. I don't really need this clamp as I made one extra just in case. But, it would be nice to have a spare.

I started all the threads on the mill and then finished them in the comfort of my living room using a power drill.

The tap is one that pushes the chips down and out. The thickness I'm tapping is about 3/4" Using M6X1 threads.

Well, I know better and did it anyhow, but I was tapping dry. On one of the pieces I got a chunk of aluminum stuck in the cutter on the back side of the piece. I've tried clearing it with all kinds of "digging it out" methods and it won't budge. Luckily I have a few of these taps so I was able to finish the rest but I'd like to free this tap. I don't really need this clamp as I made one extra just in case. But, it would be nice to have a spare.