Hello,

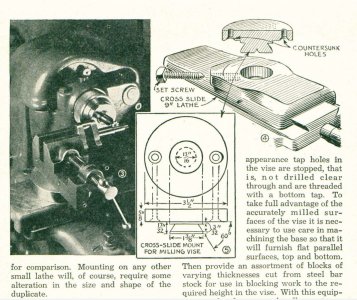

Have a look at attached picture. In particular the 60 degree cut with the 90 degree shoulder on top.

I managed to hack it out in a fairly clumsy fashion with a V tool on the compound going in at 30 degrees and a tiny cutter for the deepest part when the V tool ran out of room and hit the 90 degree shoulder.

But I reckon there must be several better ways to do it that I didnt think of.

How would you do it ?

Bill

Have a look at attached picture. In particular the 60 degree cut with the 90 degree shoulder on top.

I managed to hack it out in a fairly clumsy fashion with a V tool on the compound going in at 30 degrees and a tiny cutter for the deepest part when the V tool ran out of room and hit the 90 degree shoulder.

But I reckon there must be several better ways to do it that I didnt think of.

How would you do it ?

Bill