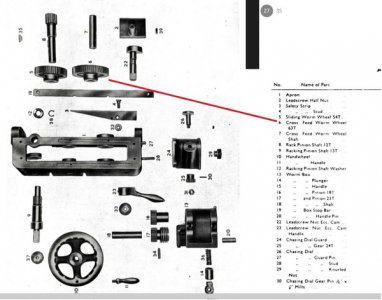

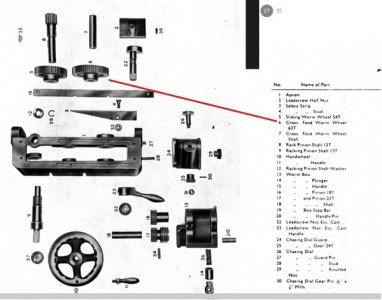

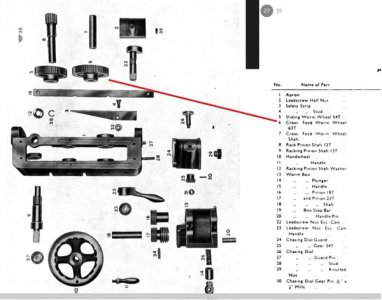

Referencing the parts layout above, power from the feed screw runs through the keyed gear #16 which meshes with gear #17. The worm on gear #17 runs either the carriage via gear #5 or the cross-feed via gear #6 when you move lever #15 to engage either one. #6 is the 63T worm gear in question. No pins, it rides on shaft #7 which is nominally 3/4".

In total, my 63T has 7-8 missing teeth 180 degrees opposed, meaning it was crashed hard enough that both the cross-slide and power feed pinion gears ripped a few teeth out each half. The power feed rod on my model has two 1/4" ball bearings pushed toward the outer diameter of the shaft by a spring. Under spring pressure, these balls catch two mating holes in a collar, driven by the gearbox, that surrounds the feed rod. This is intended to act as a clutch that slips when the carriage gear train binds up -- like during a crash. The ball bearings in mine are a lot harder than the alloy in the power feed shaft, however, and it just egged out the hole and kept spinning. Who knows how many decades ago that was, although it's interesting to piece the story of what happened together. An earlier version of this lathe just had a sacrificial split pin.