- Joined

- Nov 8, 2012

- Messages

- 783

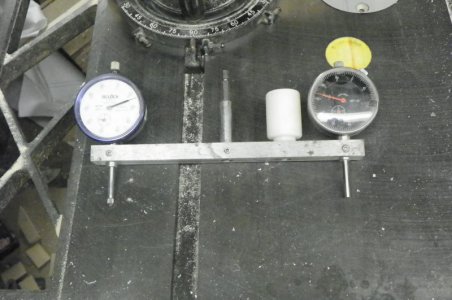

Anyone with a 8520/8530 come up with a good mod/way to tram your mill ?

Was re-tramming mine yesterday and was bit of a pain.

Eyeball it, measure, tap tap tap, re-measure, tap tap tap, re-measure. Dang !!! too far !!! Tap tap tap....

I was thinking some kind of adjustment screw mounted to the over-arm for fine adjustment and maybe a mounted protractor for initial gross adjust would make tramming much easier.

Thought I'd ask if anyone here has come up with a good design.

Was re-tramming mine yesterday and was bit of a pain.

Eyeball it, measure, tap tap tap, re-measure, tap tap tap, re-measure. Dang !!! too far !!! Tap tap tap....

I was thinking some kind of adjustment screw mounted to the over-arm for fine adjustment and maybe a mounted protractor for initial gross adjust would make tramming much easier.

Thought I'd ask if anyone here has come up with a good design.