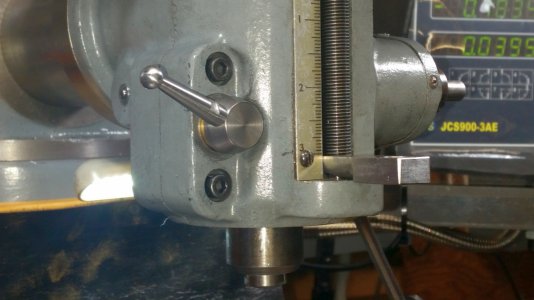

I have one of those stops In the third picture. How would you use that Dave?Yep . Here is a pic . I know this will not be new to many people on here , but it is what it is . The middle piece is milled away allowing it to slip on the screw anywhere . I have a split hinged clamp for the same purpose that must be in work as I can't find it here . Other than mounting up a dial vernier I have no problems with this set-up . Not sure if this is of any help or not .

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How-To] Clausing 8520, 8530 New Quill lock like a BP

- Thread starter woodchucker

- Start date

- Joined

- Jan 31, 2016

- Messages

- 11,478

It saves the time of using the bottom lock stops . A real PITA when using or not using the quill length . This simply slips onto the screw anywhere along the entire length . I never use the bottom lock .

- Joined

- Nov 25, 2015

- Messages

- 8,344

I get you. Thread the piece and then remove a section. I might do that. Originally I was thinking about the spring type like this. But ruled it out as not enough space even if thinned .Yep . Here is a pic . I know this will not be new to many people on here , but it is what it is . The middle piece is milled away allowing it to slip on the screw anywhere . I have a split hinged clamp for the same purpose that must be in work as I can't find it here . Other than mounting up a dial vernier I have no problems with this set-up . Not sure if this is of any help or not .

then as a more advanced project I am thinking about the button type ..

what you showed me is much simpler. And maybe I do that..

- Joined

- Nov 25, 2015

- Messages

- 8,344

Added the knob.. just need to make a handle.

Sorry, not a lot of pics of how to. But here's the details.

I had a small drop of steel. it already had a hole (not through) in it. I decided to cut off a 5/8 - 16 shouldered hex bolt..

I enlarged the hole to 15/64 if I remember correctly, reamed it. turned the bolt down to a few thou over.. pressed it into the hole dry.

put the shoulder into the lathe and shaped the part.

Then put the piece into the quill lock, tightened it as much as I could by hand , marked where it was just starting to engage.. so now its timed.

put it in the mill, set the angle level to the taper, ran a small mill across to create a flat spot, spotted it, then drilled it for 10-32... I could not find one of my 10-24 bottoming tap, so I just went 10-32..

And that's where we are now. Just need to make a handle. Oh baby, this is great.. it works as I had hoped. Much easier, more positive.

Sorry, not a lot of pics of how to. But here's the details.

I had a small drop of steel. it already had a hole (not through) in it. I decided to cut off a 5/8 - 16 shouldered hex bolt..

I enlarged the hole to 15/64 if I remember correctly, reamed it. turned the bolt down to a few thou over.. pressed it into the hole dry.

put the shoulder into the lathe and shaped the part.

Then put the piece into the quill lock, tightened it as much as I could by hand , marked where it was just starting to engage.. so now its timed.

put it in the mill, set the angle level to the taper, ran a small mill across to create a flat spot, spotted it, then drilled it for 10-32... I could not find one of my 10-24 bottoming tap, so I just went 10-32..

And that's where we are now. Just need to make a handle. Oh baby, this is great.. it works as I had hoped. Much easier, more positive.

- Joined

- Nov 25, 2015

- Messages

- 8,344

- Joined

- Nov 25, 2015

- Messages

- 8,344

I made the quill stop that Dave @mmcmdl talked about the other day.. posted it in potd.

Here's some images. I found it was not sitting tight, and looked like it was going to fall out. I could redo in AL

but I took out a woodruff key cutter and added a slot for a rare earth magnet. It was too tall to fit under the arch.. so this lowers it. The rare earth that I have a disc, does not have much magnetism on the sides, so I propped it up. It still allows me to stack a set of gauge block on the side of the magnet. I added scotch tape, so I can get swarf off. I had a magnet , and could not get the swarf off, so the tape helps.

Oh yea, added a leash to it, so if it ever does fall, it doesn't hit anything.

Here's some images. I found it was not sitting tight, and looked like it was going to fall out. I could redo in AL

but I took out a woodruff key cutter and added a slot for a rare earth magnet. It was too tall to fit under the arch.. so this lowers it. The rare earth that I have a disc, does not have much magnetism on the sides, so I propped it up. It still allows me to stack a set of gauge block on the side of the magnet. I added scotch tape, so I can get swarf off. I had a magnet , and could not get the swarf off, so the tape helps.

Oh yea, added a leash to it, so if it ever does fall, it doesn't hit anything.