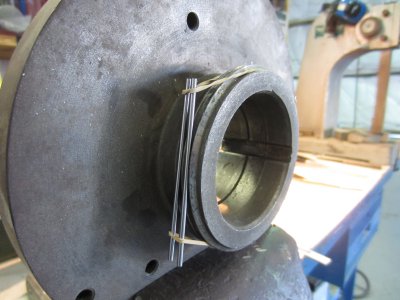

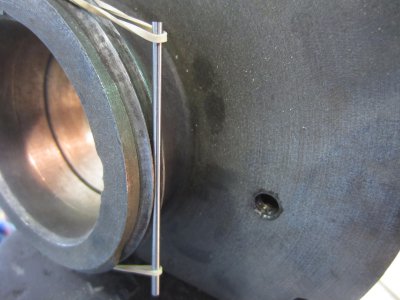

Hey JB, Here's a couple of pics I took just this morning. I hope this will helps. I'm thinking that your gearbox should be very similar to mine if not the same thing. It's a pic of the blue print I'm guessing so that it can be remade. I think it would be nice to have all that information engraved on that piece of plexiglass or whatever it is. That's what I'm intending for mine anyway.

If it isn't right then you can call clausing and ask them to send you a blue print. If you don't want to do that, let me know if you want me to make a copy and send it to you. I think your in central California, right? Your not that far away.

Ed