Hello all, I am in the process of an engine build and I want to polish 4 small camshaft. I decided it would be easier to do it on my lathe however I have never tried it before and I’m lost as to what the best method would be. I have some small live centers but not sure if they will suffice. Was hoping to get some suggestions. Thanks in advance

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chucking up a camshaft in the lathe

- Thread starter Pevehouse

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,063

First question.

Will the cam fit between centers on your lathe?

You may be best off mounting between centers and using a drive dog with some soft copper or aluminum pads to not scratch the bearings.

Will the cam fit between centers on your lathe?

You may be best off mounting between centers and using a drive dog with some soft copper or aluminum pads to not scratch the bearings.

How bad is it that you want to polish it? Maybe strips of crocus cloth (or similar) while running the lathe at low speed? Tape the end bearing (a few layers of electrical tape) grab that in a 3 jaw chuck with a tailstock center for the far end.

- Joined

- Dec 18, 2022

- Messages

- 1,729

If you are reinstalling an old cam and using the old lifters I would not do anything to it other than making certain the lifters go back onto the same lobe they were on when you tore it down, its all worn in together.Hello all, I am in the process of an engine build and I want to polish 4 small camshaft. I decided it would be easier to do it on my lathe however I have never tried it before and I’m lost as to what the best method would be. I have some small live centers but not sure if they will suffice. Was hoping to get some suggestions. Thanks in advance

Edit: further thought, a cam is harder than a witches heart and brittle, be wary they will break like glass...

I appreciate all the advice. I’m no stranger to cams in general. I’m an Automotive technician however we would usually send stuff like this out to have it done by a machinist but our machine shops we used to have, have all closed up shop. Let me clarify, I’m not looking to take anything substantial off, more less just cleaning the lobes and bearing surfaces up a touch. The crocus clothe sounds about right for what I’m looking to do. In my case I’m replacing the followers but not the cams. It has four and well, you gotta stop somewhere,lol

- Joined

- Apr 30, 2015

- Messages

- 11,329

You can't put metal back, you can only take it off. Polishing will not improve the performance of an old worn cam.

I'd use a very light abrasive like rubbing compound and a piece of cloth or denim

If you are building a model engine from scratch that's a different story altogether

I'd use a very light abrasive like rubbing compound and a piece of cloth or denim

If you are building a model engine from scratch that's a different story altogether

Last edited:

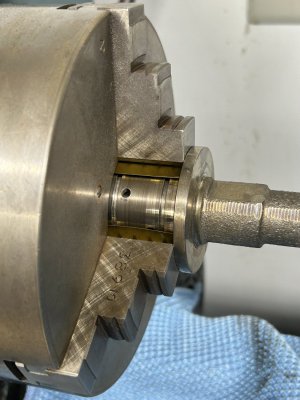

The cams have plugs in one end that’s preventing me from using a center. Really don’t want to knock that plug out because I’m not sure if they are available from ford at this moment. Just wasn’t sure if there was another way that I haven’t thought about. This is my current setup but I really want to clean up the end I’m holding it with if you follow me

Attachments

I understand, not looking to remove any metal, just to clean it up a bit. Not building this thing from scratch. It’s a 3.5 cohost engine that jumped time. Damaged one cam, so it’s being replaced. I have new followers coming. The remaining 3 cams are not worn , I’m a little OCD and hate to put them back without a little clean up. That’s just how I am when it comes to my job. Surgically clean almost.You can't put metal back, you can only take it off. Polishing will not improve the performance of an old worn cam.

If you are building an engine from scratch that's a different story altogether

- Joined

- Dec 23, 2012

- Messages

- 776

It depends on the problem.Hello all, I am in the process of an engine build and I want to polish 4 small camshaft. I decided it would be easier to do it on my lathe however I have never tried it before and I’m lost as to what the best method would be. I have some small live centers but not sure if they will suffice. Was hoping to get some suggestions. Thanks in advance

If take it a hard chrome shop the grind the bearing and chrome oversize and grind back to size . Not cheap.

If trying to save money use a tool post grinder and just a little off as possible. Use center and a steady rest on next close bearing.

Dave