- Joined

- Feb 8, 2014

- Messages

- 11,144

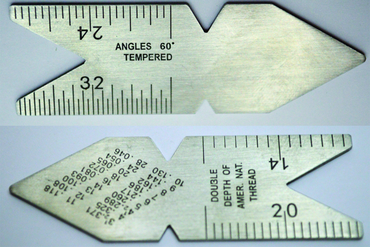

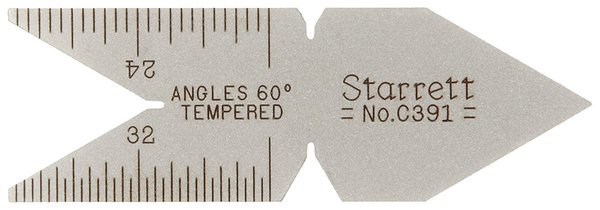

What I don't get is if the OP is using the gauge to check the threading tool and his grind, how is it bottoming out before touching both sides of the gauge?

Three possibilities that I see: 1) it's a crappy gauge with no relief in the bottom of the V, 2) the OP is grinding a 30 degree tool, 3) as said above, it's a Whitworth gauge.