Now that I can log in again... I have some caveats that I want to mention.

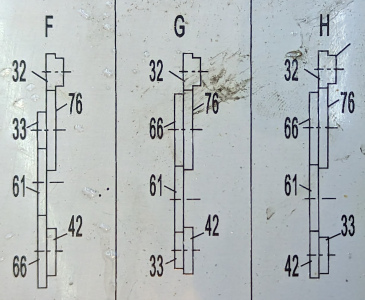

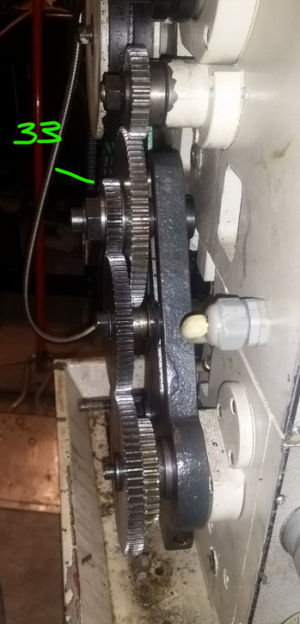

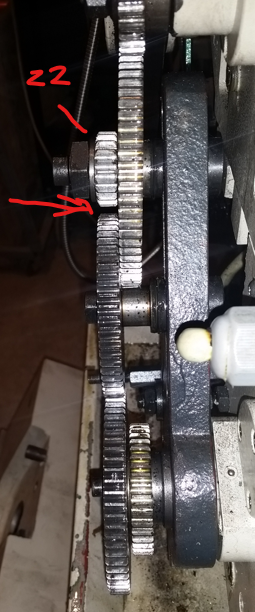

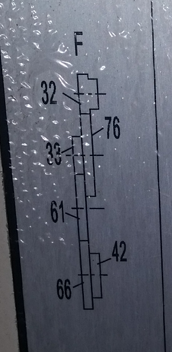

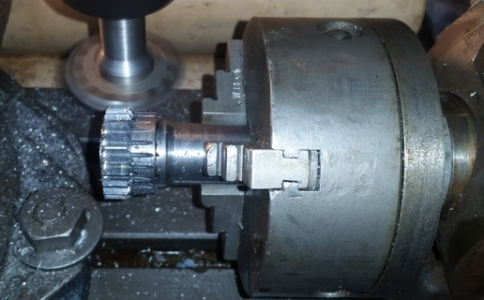

I counted teeth on only one gear; the one driven by the A/B/C selector. All the other counts are based on looking up the information in the parts list in the manual. Any mistakes or typos there will show up in mistakes here.

I did not disassemble the gearbox. Everything I wrote is based on turning things by hand with the selecting gears in the engaged positions and in intermediate positions that are disengaged.

I haven't tested this yet by calculating a gear train and validating it.

I can't trivially review correctness because I've closed the gearbox back up and refilled it with oil, so it will be a right mess again if I open it again.

I welcome feedback, correction, additional information.

I counted teeth on only one gear; the one driven by the A/B/C selector. All the other counts are based on looking up the information in the parts list in the manual. Any mistakes or typos there will show up in mistakes here.

I did not disassemble the gearbox. Everything I wrote is based on turning things by hand with the selecting gears in the engaged positions and in intermediate positions that are disengaged.

I haven't tested this yet by calculating a gear train and validating it.

I can't trivially review correctness because I've closed the gearbox back up and refilled it with oil, so it will be a right mess again if I open it again.

I welcome feedback, correction, additional information.