-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chambering short barrels in the headstock

- Thread starter LVLAaron

- Start date

- Joined

- Mar 23, 2021

- Messages

- 357

At least it's not very messy

I’ve been cleaning up constantly in the process. Like you I’ve filled a large container with chips.

- Joined

- Jan 6, 2017

- Messages

- 1,214

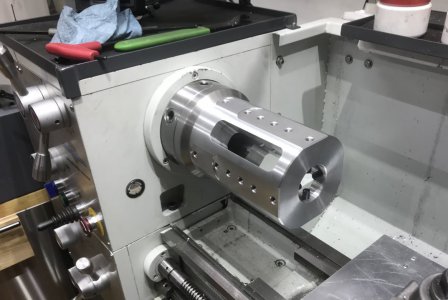

Cutting the slots for bolt handles. It’s a slow process. Sure glad I am not making this out of steel!

It’s 5” OD and 2” ID x 7” long. With the backplate it’s about 8” overall.

View attachment 402852

I noticed that you chamfered that transition.

That fixture looks great! Awesome work.

- Joined

- Feb 20, 2019

- Messages

- 335

Cutting the slots for bolt handles. It’s a slow process. Sure glad I am not making this out of steel!

It’s 5” OD and 2” ID x 7” long. With the backplate it’s about 8” overall.

Annular cutters and that slot is cut in 5 minutes.

- Joined

- Mar 23, 2021

- Messages

- 357

I’ll have to look into some of those. That would have saved some time for sure!Annular cutters and that slot is cut in 5 minutes.

- Joined

- Aug 6, 2015

- Messages

- 3,886

Now I want a set of those…Annular cutters and that slot is cut in 5 minutes.

- Joined

- Nov 17, 2020

- Messages

- 1,723

Now I want a set of those…

- Joined

- Mar 23, 2021

- Messages

- 357

- Joined

- Mar 23, 2021

- Messages

- 357

I used the same backplate as you did from Grizzly.Did you use a backplate, or mound studs directly to your fixture?

I went with three bolts that are 3/8x16, and they reach 1.5” into the aluminum. Spider holes are all 3/8 x 24.

Since the fixture is @1.5” thick, with 1.5” grub screws there will be no screw head ever protruding from the fixture just as an added safety measure.