- Joined

- Apr 6, 2011

- Messages

- 2,082

I need to spend more time in front of the lathe 'cause it seems I have too much time on my hands otherwise and I start "thinking"...

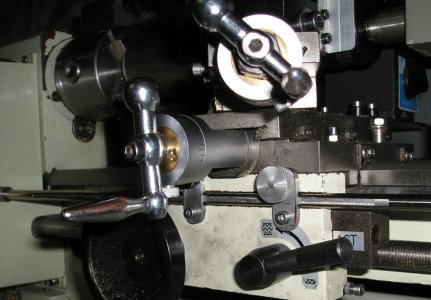

Okay, it has come to my attention that if you were to be a bit careless when threading or having the clutch engaged you could easily allow your carriage/tool post/etc. run smack into the spinning chuck. While I haven't seen it in person I imagine this is what would be called a "bad thing". :biggrin: Since this is a "bad thing" why isn't every lathe outfitted with a device to prevent this from happening?

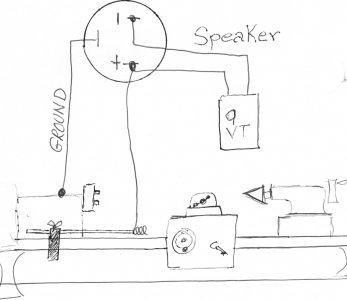

It would be simple enough to incorporate, just make a moveable carriage stop with a built in kill switch. When you do your initial setup for cutting you move the kill switch/carriage stop to the point you do not want the carriage to go past. If you happen to slip up after that point the tool post would never make it into the chuck as the power would be cut when the carriage hits the stop/switch. Being moveable it could be reset at any point depending on your tool setup or even moved out of the way if need be.

It would be very simple to fab up and certainly wouldn't cost much especially considering what the aftermath of a "bad thing" would cost.

Am I missing something basic that makes this impractical?

-Ron

Okay, it has come to my attention that if you were to be a bit careless when threading or having the clutch engaged you could easily allow your carriage/tool post/etc. run smack into the spinning chuck. While I haven't seen it in person I imagine this is what would be called a "bad thing". :biggrin: Since this is a "bad thing" why isn't every lathe outfitted with a device to prevent this from happening?

It would be simple enough to incorporate, just make a moveable carriage stop with a built in kill switch. When you do your initial setup for cutting you move the kill switch/carriage stop to the point you do not want the carriage to go past. If you happen to slip up after that point the tool post would never make it into the chuck as the power would be cut when the carriage hits the stop/switch. Being moveable it could be reset at any point depending on your tool setup or even moved out of the way if need be.

It would be very simple to fab up and certainly wouldn't cost much especially considering what the aftermath of a "bad thing" would cost.

Am I missing something basic that makes this impractical?

-Ron