- Joined

- Apr 4, 2016

- Messages

- 72

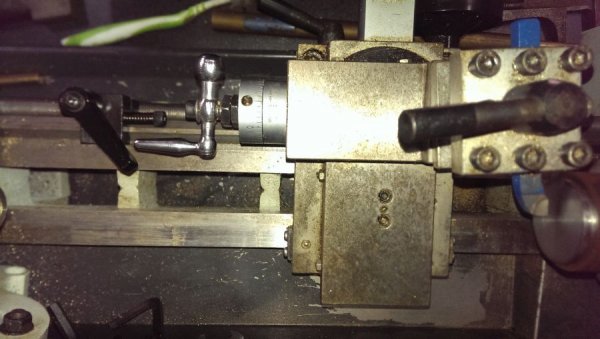

I have a Titan Lathe which is 95% + parts interchangeable with a Sieg C2/C3. My issue is the carriage lacks a stop . I saw one advertised on Ebay fairly cheaply (specifically for the Sieg) and now I have it I realise it just won't work. I particularly want to stop carriage push back to the right when manually cutting left towards the chuck or when facing.

The stop I purchased has two issues:-

1. The lever is way too tall and hits the top slide, even a substituted in short bolt catches.

2. The spring loaded stop bolt sits in a countersunk hole so does not work same if switched to right. If left (on left) the stop bolt head sits on a screw head on the carriage and obviously cannot be depth adjusted in situ.

In short, this stop is designed ONLY to sit to left side of the carriage and not the right.

I have made a quick and dirty stop (out of an old brass window frame latch) that sits middle of bed but really would like to know how others have solved this one.

Sorry for any condensation in images, warm humid morning after a chilly night. Another constant battle.

The stop I purchased has two issues:-

1. The lever is way too tall and hits the top slide, even a substituted in short bolt catches.

2. The spring loaded stop bolt sits in a countersunk hole so does not work same if switched to right. If left (on left) the stop bolt head sits on a screw head on the carriage and obviously cannot be depth adjusted in situ.

In short, this stop is designed ONLY to sit to left side of the carriage and not the right.

I have made a quick and dirty stop (out of an old brass window frame latch) that sits middle of bed but really would like to know how others have solved this one.

Sorry for any condensation in images, warm humid morning after a chilly night. Another constant battle.

Last edited: