- Joined

- Sep 8, 2019

- Messages

- 4,392

Welding coupons come in 2 varieties: flat & pipe. Welding coupons are used for intensive welding practice. The main benefit is “a *lot* of arc time with minimal prep time”.Eric, I don’t even know what a pipe coupon is…do you sell these, or store them up for the winter, or what?

The name “coupon” comes from the appearance of a flat, rectangular coupon: it is shaped like a coupon!

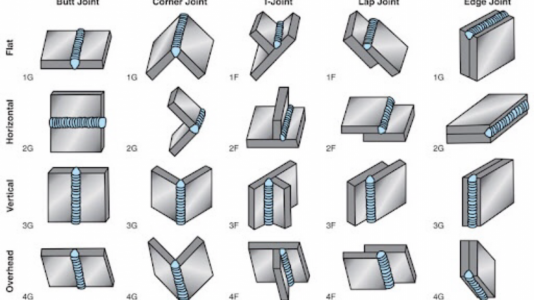

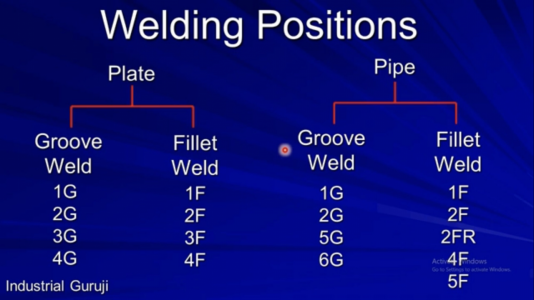

Flat coupons can be either fillet or groove. Pipe coupons are always groove. Flat, thick butt joints are always groove.

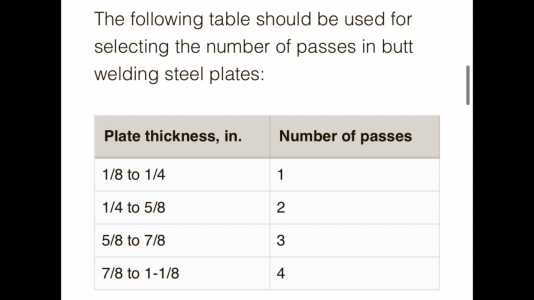

One characteristic of a groove weld on thick material is multiple passes (multiple stringer beads which make up a multi-pass weld bead).

A fillet weld can be a butt joint, T-joint, edge joint, lap joint or corner joint. A pair of flat welding coupons can quickly be oriented into any of these joints.

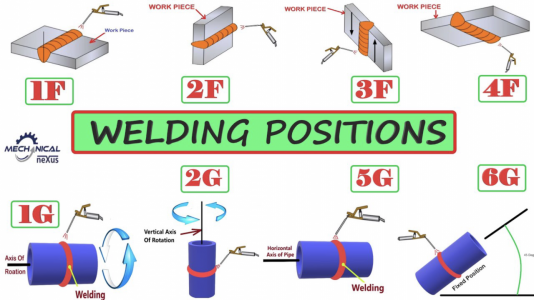

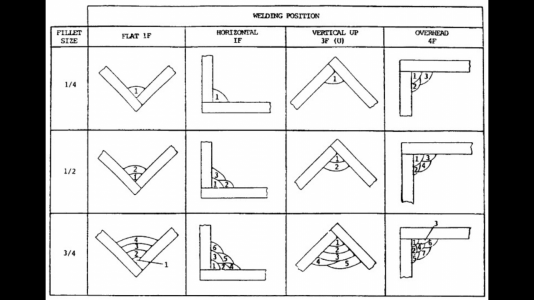

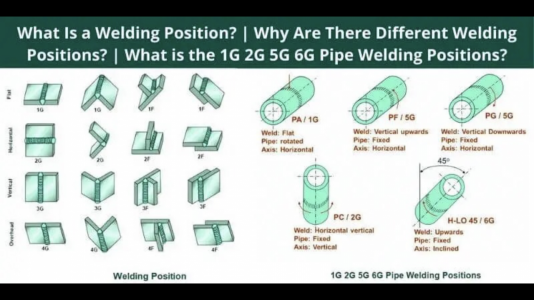

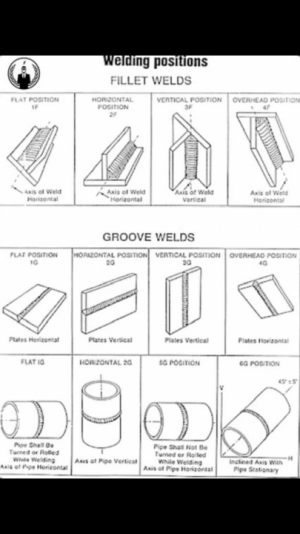

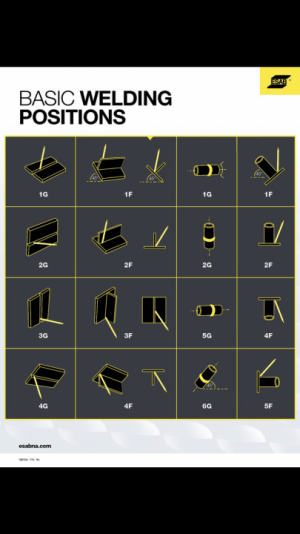

With flat welding coupons, you can easily orient them in the (1) flat, (2) horizontal, (3) vertical or (4) overhead welding positions.

Fillet is “F”, and groove is “G”.

So, for example, a fillet groove weld in a flat position is 1F. A groove weld (this would be thick material) in a flat position is 1G. A fillet weld in the overhead position is 4F, and so on.

Pipe welds are usually “5G” or “6G”. 5G is fixed horizontal, and 6G is fixed at a 30° angle. “Fixed” means that you are not allowed to rotate the pipe after it is tacked.

I sell the 8” coupons because I have never seen anything larger than 6” for sale.