- Joined

- Jun 26, 2018

- Messages

- 1,733

Thanks @RJSakowski

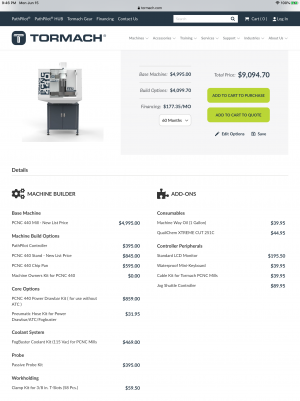

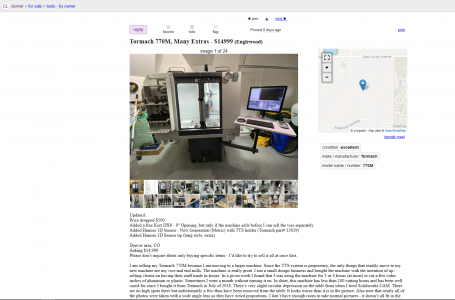

I don't think there are many machines out there that are flawless, that owners couldn't give you a laundry list of nit-picks. Some of yours are concerning, some are, just caulk it up to normal wear and tear. I don't want to upgrade to the 770. My reasoning is, the 440 which is advertised as $5400 end up being 7k+ not even decked out. The 770 would be 12k plus. I do have 14k after taxes, but I have other goals with the leftover. How opposed are you to the 440? I don't know what the future holds, but for the last few years and foreseeable future, I tend to end up with parts under 3"sq. Titanium and stainless are a must and d them well. I know very little about cnc, this is my "get my hands dirty" stage.

It comes down to, I want a capable machine for the 3"sq sized projects and stainless/Ti ready machine. I might even sell my pm727 which would fetch a solid 2-$2500 which I would dump into this in after the sale upgrades. Its too bad their stand and enclosure are so damn expensive, but they are nice and a must really.

I should jump on those other sights but its tough being the new guy and I like it here...

I don't think there are many machines out there that are flawless, that owners couldn't give you a laundry list of nit-picks. Some of yours are concerning, some are, just caulk it up to normal wear and tear. I don't want to upgrade to the 770. My reasoning is, the 440 which is advertised as $5400 end up being 7k+ not even decked out. The 770 would be 12k plus. I do have 14k after taxes, but I have other goals with the leftover. How opposed are you to the 440? I don't know what the future holds, but for the last few years and foreseeable future, I tend to end up with parts under 3"sq. Titanium and stainless are a must and d them well. I know very little about cnc, this is my "get my hands dirty" stage.

It comes down to, I want a capable machine for the 3"sq sized projects and stainless/Ti ready machine. I might even sell my pm727 which would fetch a solid 2-$2500 which I would dump into this in after the sale upgrades. Its too bad their stand and enclosure are so damn expensive, but they are nice and a must really.

I should jump on those other sights but its tough being the new guy and I like it here...