- Joined

- Sep 8, 2019

- Messages

- 4,392

Next week I will be calling the local steel yard to order a lot of .120” thick, 3” X 4” mild steel pre-cut coupons. They will sell me the sheet & cut it on their behemoth press brake.

I have been going to this place for 20+ years, & they are pretty reasonable for material & labor costs.

I will post here what I ended up paying by the pound for these pre-cut coupons, but here are some questions:

(1) What size coupon would *you* choose? I use these for joint & position practice for MIG, TIG, stick & gas welding. Right now I am working on 1F (i.e. flat horizontal). I do butt, lap, corner, edge, & T-joints. No bevel on .120”, obviously.

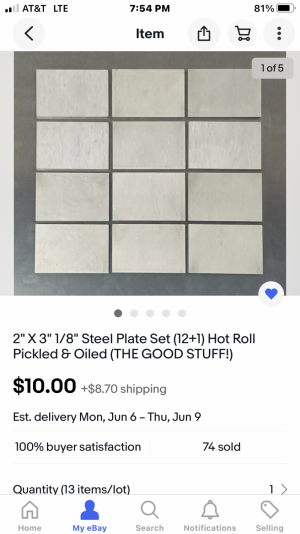

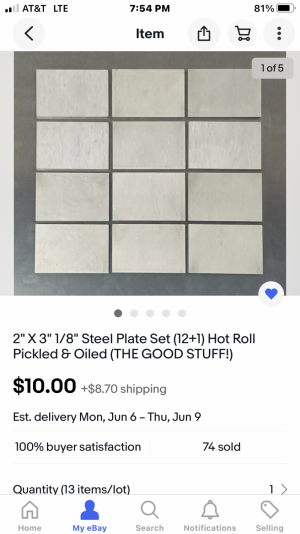

(2) Is this a good plan to order from the steel yard? They sell nice pickled & oiled coupons online (see screenshot), but they are very expensive.

(3) How would *you* prep these coupons? I *always* remove all the mill scale. I have been using a flap disk on a 4-1/2” angle grinder, but I am going to try to use a milling machine. I will process them in bulk.

(4) I will sell some to interested forum members at my cost. You remove the mill scale. Local pickup is best, but I will ship to US addresses.

(5) Any cost effective ideas on re-using these after I weld them? Pipe welding coupons easily lend themselves to re-use if you don’t mind filler material in your coupon. I could use the scrap for torch cutting practice & then take to a scrapper to be recycled.

I have been going to this place for 20+ years, & they are pretty reasonable for material & labor costs.

I will post here what I ended up paying by the pound for these pre-cut coupons, but here are some questions:

(1) What size coupon would *you* choose? I use these for joint & position practice for MIG, TIG, stick & gas welding. Right now I am working on 1F (i.e. flat horizontal). I do butt, lap, corner, edge, & T-joints. No bevel on .120”, obviously.

(2) Is this a good plan to order from the steel yard? They sell nice pickled & oiled coupons online (see screenshot), but they are very expensive.

(3) How would *you* prep these coupons? I *always* remove all the mill scale. I have been using a flap disk on a 4-1/2” angle grinder, but I am going to try to use a milling machine. I will process them in bulk.

(4) I will sell some to interested forum members at my cost. You remove the mill scale. Local pickup is best, but I will ship to US addresses.

(5) Any cost effective ideas on re-using these after I weld them? Pipe welding coupons easily lend themselves to re-use if you don’t mind filler material in your coupon. I could use the scrap for torch cutting practice & then take to a scrapper to be recycled.