- Joined

- Nov 27, 2012

- Messages

- 7,856

darkzero, does that mean your going to do something custom to mount the z-axis to the quill? i know it's going to be something good. I really like all the custom things you're doing with your mill and lathe.

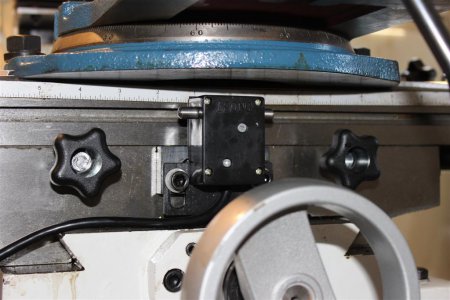

Got my ES-12 today! I have some ideas but I need to open up the ES-12 first to verify if I can even add an extra axis to it assuming that's what the "U" can be used for. I just got it mounted up & need to go through the manual. I don't want to eliminate the column Z readout in exchange for the quill Z readout. If it's not possible I'll stick to my setup now.

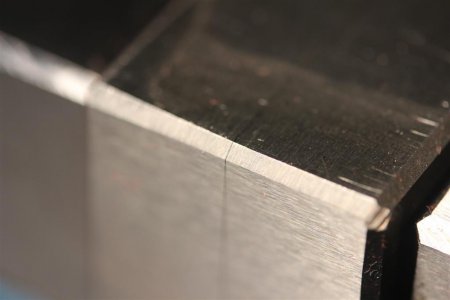

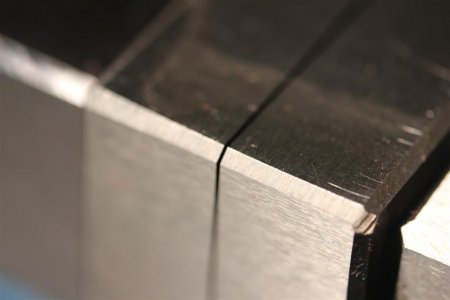

Here that are side by side. I don't like that that handle in the front is 5" lower than my old one. The heads on both are at their lowest.

Looking good! Base looks beefy! Love the side by side pic. I guess the Taiwanese are taller than the Chinese? I'm Chinese but made in America and without the riser it was too short for me.

:rofl: