Hi, I’ve recently been lucky and now own a Bridgeport shaping head…..so it’s all new to me! I’m really confused how to insert the cutters into the head, particularly the actually cutting face orientation to the head. I’ve read that if I get it wrong its not a good day, so would like to make sure on my first adventure I’ve put the cutter in the right way around. I’m going to have a go at cutting a keyway.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bridgeport Shaping Head cutter orientation

- Thread starter Deema

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,058

The one I had access to, back in the dark ages, worked vertically, facing toward the operator, although right to left could have been used, too. Keyway in a gear, for instance. The most difficulty was getting a tool ground properly so it didn't drag on the sides.

- Joined

- Nov 5, 2016

- Messages

- 1,419

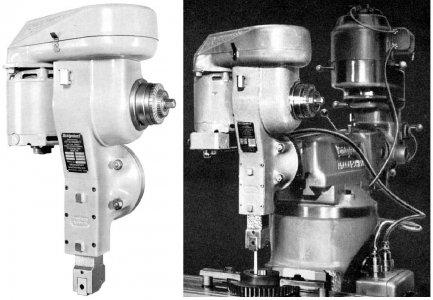

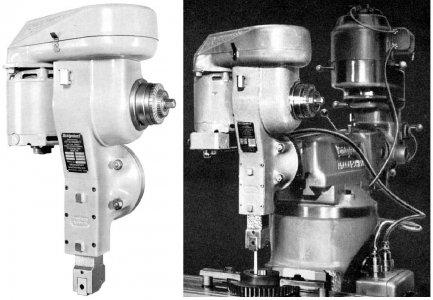

I've never used one, but here's a picture that shows the cutting tool and it appears that the cutting pressure is against the back, towards the machine. This makes sense, since you want the pressure primarily against the most solid member... I certainly don't think you would want the cutting pressure against the screwed on cover way...

Ted

Ted

- Joined

- Jan 31, 2016

- Messages

- 11,472

The shaper head is hinged and takes a .625 shank tool . The tool is ground with a flat to orientate it in the ram . It's a pretty expensive toy these days , nice to have , maybe not practical .

I'll post a pic of some tools I made up for the head in a minute .

I'll post a pic of some tools I made up for the head in a minute .

- Joined

- Jan 31, 2016

- Messages

- 11,472

Thanks all, so, in summary, the cutting edge is on the side where you hole in the ram is…..where you screw in the set screw to fix the cutter. Got it.

Another question, if I may. The spring seems to not have enough tension, I’ve again read that this adjustable, but not how to adjust it. Anyone done it? Can advise how to apply some tension?

Another question, if I may. The spring seems to not have enough tension, I’ve again read that this adjustable, but not how to adjust it. Anyone done it? Can advise how to apply some tension?

- Joined

- Jun 7, 2013

- Messages

- 10,101

High tension by the spring is not essential, nor is the relief feature, I have a Pratt & Whitney 6" vertical shaper which has relief and the ability to limit it and lock it out entirely if desired, and also have a Brown & Sharpe slotting attachment for my #2 universal mill, it has no relief feature and works just fine without it, you just have to do the feeding at the top end of the cut with the whole cutting edge exposed. With the P&W, the lateral cuts can be fed automatically as on a horizontal shaper, that is, on the return stroke.

- Joined

- Jan 31, 2016

- Messages

- 11,472

The spring tension lets the tool retract on the up stroke and has nothing to do with the cutting force . Yes , the business end of the tool faces the set screw hole in the front of the ram .