I just completed a project to adapt a "standard" Bridgeport power feed from Amazon to my column mill. First, all of credit goes to Ray (RDEAN). I saw what he had in his shop. Some of the details are different but the idea was all his... Thanx again.

When searched the forums for a solution I could find anything in this area. Maybe this will be helpful for others.

The first thing that I learned was that the inner cog wheel controls the lead screw end play. I decided to leave it in place work with it. I made a bar that fit over the 5/8" shaft and had the mate to the cog wheel.

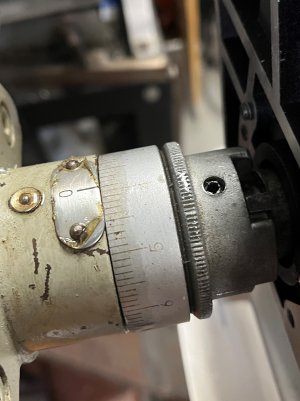

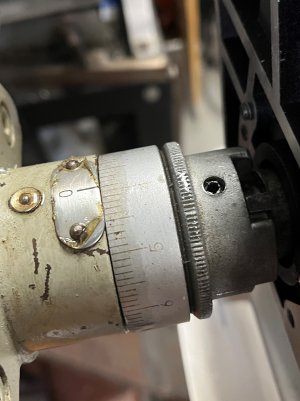

The power feeds all assume that they are being mounted to a Bridgeport. There are details that they don't explain. They assume that there is a feature on the Bridgeport shaft that they use as a reference. I had to recreate that by reverse engineering the power feed. In the end I ended up with a shaft that mimicked the Bridgeport close enough for everything to work. This is what it looked like.

After that it was a matter of getting the mounting figured out. One issue I ran into was that the gear mesh on the drive between the main drive gear and the pinion is set with shims. It is completely blind. All you can do is play with the shims until it feels good.

I used threaded rod as the primary mounting points. Mostly because it was what I had. The upside is that it allowed me to fine tune the alignment of the unit to the bed.

I decided to keep it tight to the bed. In hind sight that was probably a goof. The power feed hangs down and hits the base and when I move to the left. I lose a couple of inches of travel. I reality I will probably never miss it but I could have done it differently.

In the end it works great. Everything in smooth with no unevenness when I rotate the lead screw.

Thanx for looking. Maybe this will give others ideas.

Will

When searched the forums for a solution I could find anything in this area. Maybe this will be helpful for others.

The first thing that I learned was that the inner cog wheel controls the lead screw end play. I decided to leave it in place work with it. I made a bar that fit over the 5/8" shaft and had the mate to the cog wheel.

The power feeds all assume that they are being mounted to a Bridgeport. There are details that they don't explain. They assume that there is a feature on the Bridgeport shaft that they use as a reference. I had to recreate that by reverse engineering the power feed. In the end I ended up with a shaft that mimicked the Bridgeport close enough for everything to work. This is what it looked like.

After that it was a matter of getting the mounting figured out. One issue I ran into was that the gear mesh on the drive between the main drive gear and the pinion is set with shims. It is completely blind. All you can do is play with the shims until it feels good.

I used threaded rod as the primary mounting points. Mostly because it was what I had. The upside is that it allowed me to fine tune the alignment of the unit to the bed.

I decided to keep it tight to the bed. In hind sight that was probably a goof. The power feed hangs down and hits the base and when I move to the left. I lose a couple of inches of travel. I reality I will probably never miss it but I could have done it differently.

In the end it works great. Everything in smooth with no unevenness when I rotate the lead screw.

Thanx for looking. Maybe this will give others ideas.

Will