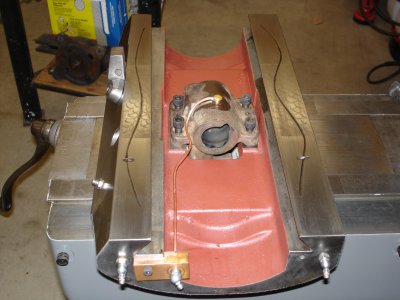

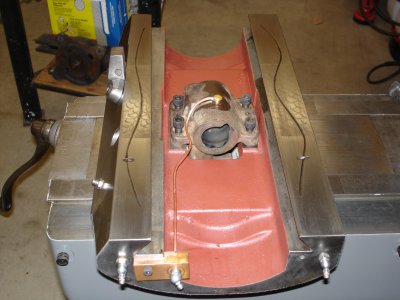

Thought I would try to post some photos of my 1958 Bridgeport rebuild. This project took about 10 weeks to complete. It was a lot work but the results were worth it! The machine was sitting for several years and needed alot of cleaning. One photo shows the machine before I took possession and the rest are of the rebuild.

Thanks for looking.

David

Thanks for looking.

David