- Joined

- Nov 25, 2015

- Messages

- 8,317

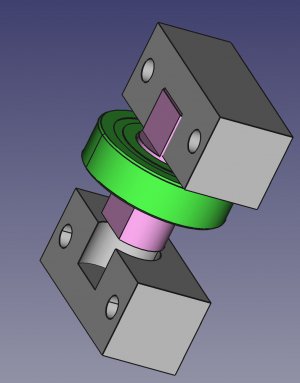

nice welds.. they look good. I realize a grinder helps, but I'm looking at the beads at the bottom of the 45 and it looks good.Got one of the end-trucks painted. I won't claim to be more than a hobby machinist at best, but a painter I ain't. Period.

Paint is still pretty soft, it'll need a week or so to really harden. Didn't really mean to duplicate Dewalts color scheme, just wanted a hi-vis yellow for the moving parts. The static parts are white, as is the ceiling. The bridge beam will be this same yellow.

View attachment 455100