- Joined

- Dec 18, 2019

- Messages

- 6,527

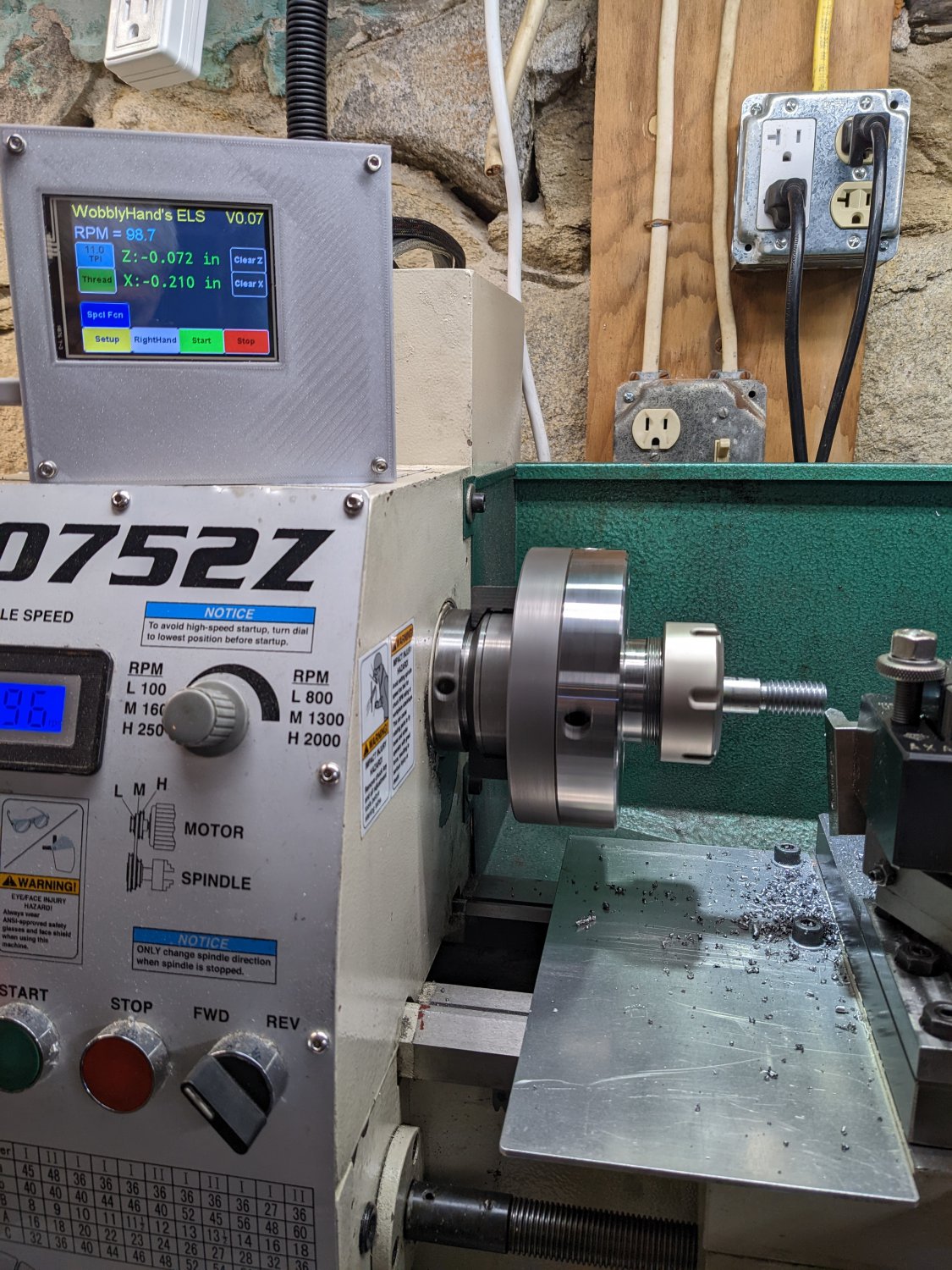

Just because I could, I cut an 11 TPI thread on my lathe using my home made Electronic Lead Screw, using the new box on my lathe.

Pretty happy with this. Thread came out nice too.

Pretty happy with this. Thread came out nice too.