- Joined

- Sep 10, 2020

- Messages

- 34

Greetings, folks.

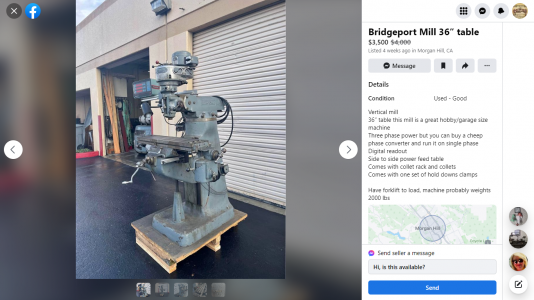

I've been spending time researching and rebuilding knee mills smaller than the Bridgeport class mill, as my available space is limited. Once again, I'm looking at the BP for a possible solution.

The smallest BP is the original round RAM model with the M head. I'm sure I could make the M head work, but would rather have a pulley J head with R-8 spindle. I would also rather have a dovetailed RAM. Trouble is, I've not seen any dovetail RAM Series 1 mills with a smaller than 42" table. The lathe-UK site says there were 36" and 32" tables made and 2 sizes of knees for 9" and 12" cross-feed saddles. Were these offerings just for the UK market?

The smaller 36" table and even a 9" cross-feed knee would work for me. Any thoughts or ideas on sourcing these items?

I've been spending time researching and rebuilding knee mills smaller than the Bridgeport class mill, as my available space is limited. Once again, I'm looking at the BP for a possible solution.

The smallest BP is the original round RAM model with the M head. I'm sure I could make the M head work, but would rather have a pulley J head with R-8 spindle. I would also rather have a dovetailed RAM. Trouble is, I've not seen any dovetail RAM Series 1 mills with a smaller than 42" table. The lathe-UK site says there were 36" and 32" tables made and 2 sizes of knees for 9" and 12" cross-feed saddles. Were these offerings just for the UK market?

The smaller 36" table and even a 9" cross-feed knee would work for me. Any thoughts or ideas on sourcing these items?