- Joined

- Oct 17, 2018

- Messages

- 922

I have acquired an Atlas Craftsman 101.27440 lathe. I bought it for the QCGB to put on my 101.07403.

Questions:

1. Is the difference between a 27440 and a 07403 that one has a QCGB and one does not? They have the same parts manual.

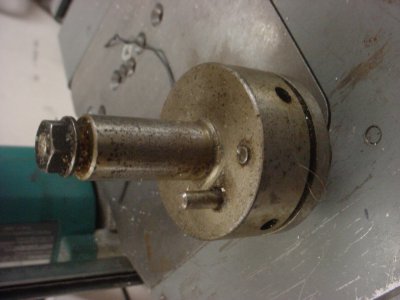

2. What is this turret tailstock? The lathe came with some sort of turret tailstock. You move the handle to advance the tool. there's a little "Gatling Gun"-type contraption on the right that rotates and clicks with detents. I can't figure out what it does. Here are some pictures from various angles:

I haven't unloaded it yet from my truck or taken any of the tools off. It is not sliding easily off the lathe bed, but it will move when tapped with a rubber hammer. There are no easily identifiable marks or anything on it, but it does have grime and surface rust. It seems to move easily, but I haven't really played with it much.

3. Are these tools part of the turret tailstock?

The lathe came with tons of tooling. These were stored as you see them in the green Styrofoam and I think they go to the turret tailstock. I can take more close-ups later. I should note the seller had a mill as well, but he was selling all this as part of the lathe, so I think it goes with the lathe. The bits on the right appear to be some sort of grinder/polisher bits.

4. Which of these faceplates should I keep for my lathe?

There are 5 total. They appear to have 1-3/8" diameter threads (except one as noted). I'll have to confirm they fit after I clean them.

Upper left: 7-3-/8" diameter

Lower left: 8"

Top Right: 4", appears to have a smaller thread diameter

Mid Right: 6-1/2", has LA-170-1 cast into it.

Bottom right: 5-1/8"

5. Which chucks should I keep?

I have 7 chucks as well (only 6 are shown). Only 3 have keys. At least two of them use a hex drive. Why would someone have so many chucks? I already have a 3- and a 4-jaw.

I also have a bunch of tool post tool holders, drill chucks and some other stuff I will post later.

I would like to clean up and sell most of this to offset the cost of the lathe. I bought it for the QCGB. I thought I would take the QCGB off and mount it to my machine and put the non-QCGB parts on the one I bought. Then, I'll clean the lathe up and sell it. I thought I might sell the turret tailstock tool post separately, but let me know if I should do otherwise. I would also like to sell some of the other stuff I don't already have as well.

More to come as I go through it all. I'd like to clean the grease and rust off and look for brands and part/model numbers.

Questions:

1. Is the difference between a 27440 and a 07403 that one has a QCGB and one does not? They have the same parts manual.

2. What is this turret tailstock? The lathe came with some sort of turret tailstock. You move the handle to advance the tool. there's a little "Gatling Gun"-type contraption on the right that rotates and clicks with detents. I can't figure out what it does. Here are some pictures from various angles:

I haven't unloaded it yet from my truck or taken any of the tools off. It is not sliding easily off the lathe bed, but it will move when tapped with a rubber hammer. There are no easily identifiable marks or anything on it, but it does have grime and surface rust. It seems to move easily, but I haven't really played with it much.

3. Are these tools part of the turret tailstock?

The lathe came with tons of tooling. These were stored as you see them in the green Styrofoam and I think they go to the turret tailstock. I can take more close-ups later. I should note the seller had a mill as well, but he was selling all this as part of the lathe, so I think it goes with the lathe. The bits on the right appear to be some sort of grinder/polisher bits.

4. Which of these faceplates should I keep for my lathe?

There are 5 total. They appear to have 1-3/8" diameter threads (except one as noted). I'll have to confirm they fit after I clean them.

Upper left: 7-3-/8" diameter

Lower left: 8"

Top Right: 4", appears to have a smaller thread diameter

Mid Right: 6-1/2", has LA-170-1 cast into it.

Bottom right: 5-1/8"

5. Which chucks should I keep?

I have 7 chucks as well (only 6 are shown). Only 3 have keys. At least two of them use a hex drive. Why would someone have so many chucks? I already have a 3- and a 4-jaw.

I also have a bunch of tool post tool holders, drill chucks and some other stuff I will post later.

I would like to clean up and sell most of this to offset the cost of the lathe. I bought it for the QCGB. I thought I would take the QCGB off and mount it to my machine and put the non-QCGB parts on the one I bought. Then, I'll clean the lathe up and sell it. I thought I might sell the turret tailstock tool post separately, but let me know if I should do otherwise. I would also like to sell some of the other stuff I don't already have as well.

More to come as I go through it all. I'd like to clean the grease and rust off and look for brands and part/model numbers.