Hey Everyone,

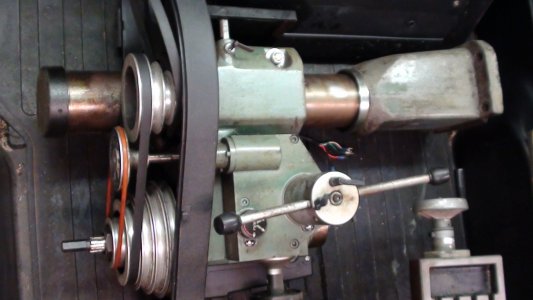

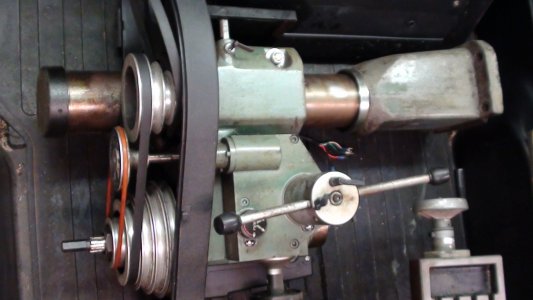

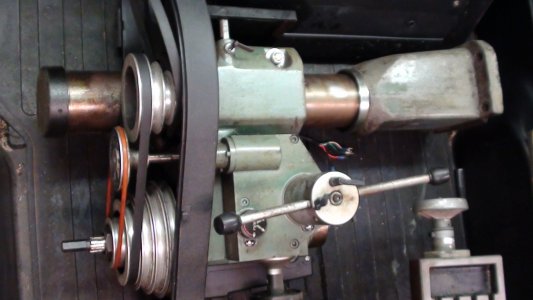

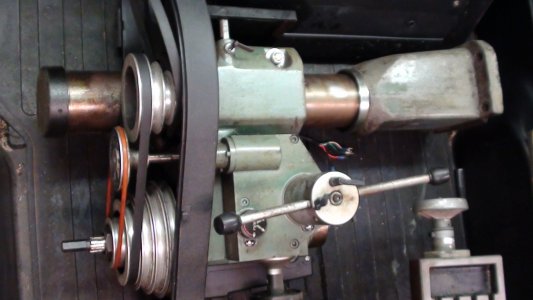

I'm a newbie to the forum. Thought I would share my latest two craiglist purchases. Interested in opionions on how I did cost wise. I know everyone likes pictures so I included a few. First is an Atlas 3991 lathe I bought from a retired gentleman. He used it to cut armatures on power tool motors. I got it for $550 with some tooling. Came with 3 and 4 jaw chucks, straight left and right bit holders, boring bar holder, faceplate and a bunch of extra gears I assume was standard with purchase when it was new. The lathe seems pretty tight. A few minor nicks in the ways under the spindle but otherwise looks like it has been reasonably cared for. I'm waiting for some new grommets from clausing to set it on before I level the base and get everything hooked up and ready to run.

The milling machine was really an unplanned purchase. I have some future projects planned now that I have the lathe but they also will require some light milling. After looking at the crazy prices people were asking for the milling attachment for the lathe, I was looking on craigslist and saw this mill pretty close by and went over to take a look at it. It has some light corrosion issues I'm hoping will mostly cleanup. The motor is 3 phase but came with a static convertor. Only tooling is a collet set. It also came with the stand. The table seems tight enough I pulled around on it and didn't notice any real play either direction. It has a power vertical feed. It ran smooth when turned on. Hoping I didn't buy a boat anchor. I know even less about mills than lathes when it comes to knowing what to look out for. I ended up getting it for $300 which seemed cheap enough. I had to seperate the head from the table because the thing is just too darn heavy. It's going in my basement with the lathe so I have to get it down the stairs. I see a lot of grumbling on here about the round column mills which I'm sure I will come to see why. As with any of these used tools you really don't know what you have until you run it some. Comments welcome good or bad. Hopefully I'm not breaking any rules by discussing a mill here with the lathe.

Cheers

I'm a newbie to the forum. Thought I would share my latest two craiglist purchases. Interested in opionions on how I did cost wise. I know everyone likes pictures so I included a few. First is an Atlas 3991 lathe I bought from a retired gentleman. He used it to cut armatures on power tool motors. I got it for $550 with some tooling. Came with 3 and 4 jaw chucks, straight left and right bit holders, boring bar holder, faceplate and a bunch of extra gears I assume was standard with purchase when it was new. The lathe seems pretty tight. A few minor nicks in the ways under the spindle but otherwise looks like it has been reasonably cared for. I'm waiting for some new grommets from clausing to set it on before I level the base and get everything hooked up and ready to run.

The milling machine was really an unplanned purchase. I have some future projects planned now that I have the lathe but they also will require some light milling. After looking at the crazy prices people were asking for the milling attachment for the lathe, I was looking on craigslist and saw this mill pretty close by and went over to take a look at it. It has some light corrosion issues I'm hoping will mostly cleanup. The motor is 3 phase but came with a static convertor. Only tooling is a collet set. It also came with the stand. The table seems tight enough I pulled around on it and didn't notice any real play either direction. It has a power vertical feed. It ran smooth when turned on. Hoping I didn't buy a boat anchor. I know even less about mills than lathes when it comes to knowing what to look out for. I ended up getting it for $300 which seemed cheap enough. I had to seperate the head from the table because the thing is just too darn heavy. It's going in my basement with the lathe so I have to get it down the stairs. I see a lot of grumbling on here about the round column mills which I'm sure I will come to see why. As with any of these used tools you really don't know what you have until you run it some. Comments welcome good or bad. Hopefully I'm not breaking any rules by discussing a mill here with the lathe.

Cheers