They used to sell that at the fastener supply that I used years ago. I never used them, but they're pretty cool. Until you see the price.

They thought highly of them, but said they became hard to see in oily/greasy environments. But outside of that, they loved them for life/safety applications that were trouble prone.

That store was more than a "nuts and bolts" store though. They did a lot of engineering for "hanging things". Mechanical systems in huge buildings was their bread and butter. I miss that place. At one point, probably 20 years ago I was buying a box of lug studs from them, I said something off hand and probably sarcastic about tire shops, truck wheel nuts, and big ugga duggas, service procedures, and my five foot torque wrench. The guy said that the store had "upgraded" to a skidmore branded tester due to agency approvals, and handed me a box with an older apparently not as widely recognized brand of ring cylinder type clamp load gauge and let me play with it for a couple of weeks. Holy crap was that enlightening. I mean, I always knew the concepts... But to see it, and to see the difference between good and bad practice... Wow. I miss that kind of place. I fully understand why they had to close their doors to walk in retail, as at that time it made no sense for them (and at that time there was a Fastenal not far, so they didn't really leave anybody stranded for either). Technically they're still there, but I miss them.

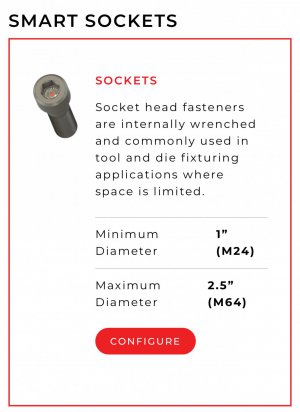

Like I say though, I never used smart bolts, but somewhere I'm sure they have a place. Given the transitions in the work force over the last few decades, where "give a chits" are rare, and preventative maintenance is more about tickinng a box as long as you "feel like" everything's probably OK, those bolts are probably saving lives "somewhere. They start out pretty large and get bigger from there, covering sizes that are pretty hypothetical in my world.

smartbolts.com

smartbolts.com