- Joined

- Sep 1, 2023

- Messages

- 68

I'm considering getting a used ZAY7045 mill with a 3phase 575v motor that I will need to replace, as I only have single phase 240v and 120v.

It is a gear head mill, with two gear knobs/levers (H, L) and (S1, S2, S3), for 6 combinations (see photo).

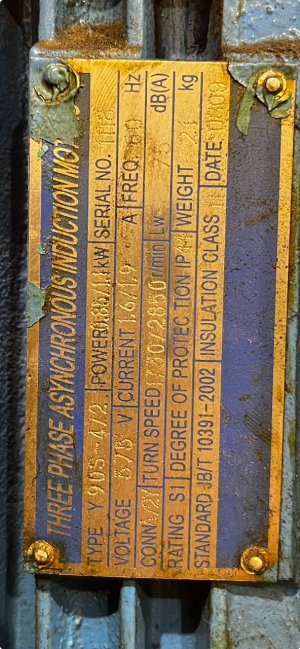

The motor plate has 2 numbers for RPM: 1730 amd 2850.

It's not clear if that means the motor has 2 wiring for each speed, or if the speed change is entirely driven by gears.

Needless to say, If the motor has 2 speed configuration, it will be harder to find a 3-phase motor that has the same specs.

Questions:

1) If I get a 3-phase motor with 1740 RPM, and a VFD, am I likely to get problems running it at 2850 RPM ?

2) How about a BLDC motor with a controller ? I see kits at reasonable price, with controllers, would like to get recommendations.

It is a gear head mill, with two gear knobs/levers (H, L) and (S1, S2, S3), for 6 combinations (see photo).

The motor plate has 2 numbers for RPM: 1730 amd 2850.

It's not clear if that means the motor has 2 wiring for each speed, or if the speed change is entirely driven by gears.

Needless to say, If the motor has 2 speed configuration, it will be harder to find a 3-phase motor that has the same specs.

Questions:

1) If I get a 3-phase motor with 1740 RPM, and a VFD, am I likely to get problems running it at 2850 RPM ?

2) How about a BLDC motor with a controller ? I see kits at reasonable price, with controllers, would like to get recommendations.

| I | II | |

| L1 | 90 | 180 |

| L2 | 200 | 400 |

| L3 | 300 | 600 |

| H1 | 550 | 1100 |

| H2 | 960 | 1920 |

| H3 | 1700 | 3400 |