- Joined

- Sep 23, 2010

- Messages

- 619

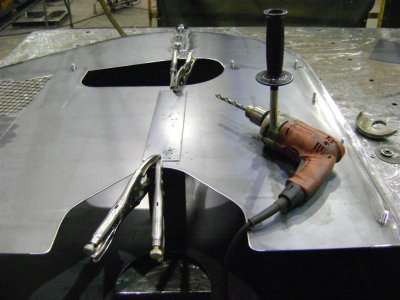

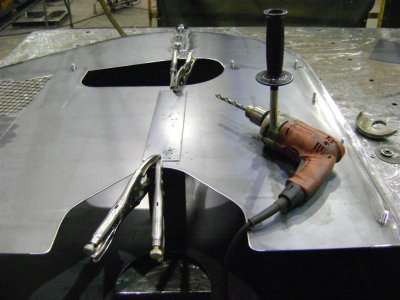

Many moons ago i was a sheet metal worker and made 100's of these over the years. Well today i was called to duty to make a few more right away. So anyway here are a few pics on how they are made. Layed out from a sheet of 14 ga black steel then the side is wrapped around the layout line and tacked. Then it is 100% welded inside and all of the excess trimmed off the outside. Then an identical sheet that has the same layout except reversed is layed on the top of the bench and the sheet with the side is tacked the same way to it. Then it has the big hole cut out with a nibbler so i can get my head inside and weld it 100%. Then it is trimmed on the outside also. Now some more layout work and a few more cut outs with the nibbler and wizz wheel on a grinder. Then the guard is split longways and angle tacked to bolt it back together. Some exp metal is added as well as some bolts and nuts and it is pretty much done adding some handles and a few mounting brackets...Bob