- Joined

- Oct 4, 2020

- Messages

- 484

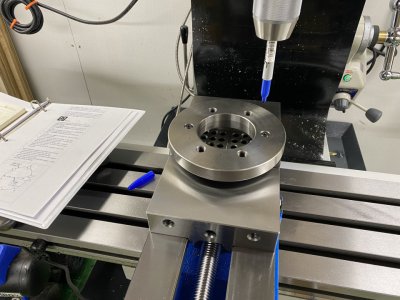

Working on this D1-5 backplate. I need to drill clearance holes and counterbore for the bolt head. For either 3/8-24 or 1/2-20 (haven't decided yet) machine bolts.

What's the "best" process for this? is this a two step op, clearance hole with one tool, counterbore with another? or is there a specific tool for the job? If not, what tool to drill the counterbore? HSS end mill?

Backplate is cast iron fwiw