- Joined

- Jul 28, 2017

- Messages

- 2,383

Were the PCBs you used 'off the shelf' or special made? If special, from where?

Thanks

Aaron

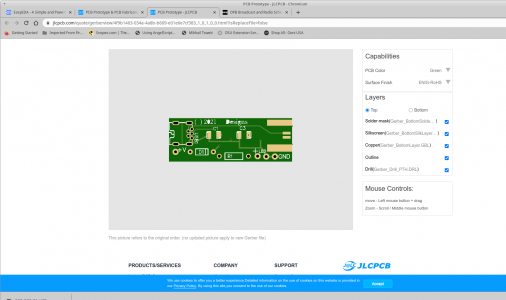

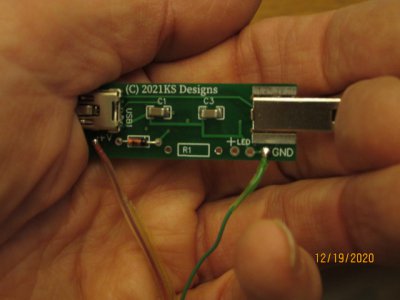

I designed the PCB myself. I used EasyEDA, which is a web-hosted EDA system. It has plusses and minuses. On the plus side, it's free (with caveats), has a fairly large part library, and, since it's browser- based it can be used with just about any computer operating system. It's got an autorouter but I didn't like the result when I tried it. You get some choices w/regard to board color and thickness, which was useful when it came to adapting the cable-specific USB jack to my PCB. They have a "cutout" feature that also was quite handy in that regard.

Negatives are: the PCB manufacturer is in China so delivery times can be on the slow side; and the free version doesn't allow private designs (that's the caveat I mentioned), so any EasyEDA user can view your designs. That doesn't mean they could use your design -- if you don't include any comments it could be pretty difficult to figure out just what it's for! If you take this route make sure you have your own notes so YOU can figure it out

You can use your own PCB design S/W like Eagle, or KiCad to generate Gerbers that you can send to their PCB manufacturer. That way you can protect your IP a little more, but still get really inexpensive boards.