- Joined

- Dec 21, 2013

- Messages

- 23

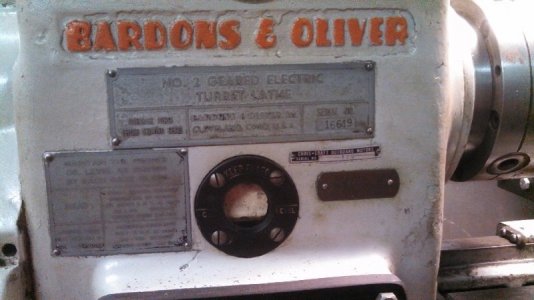

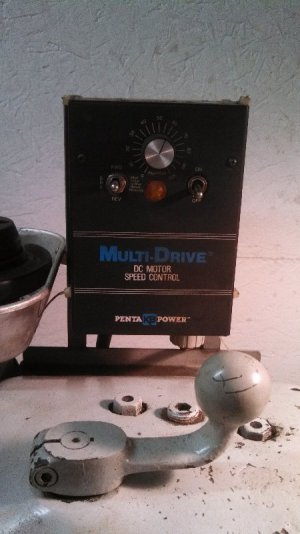

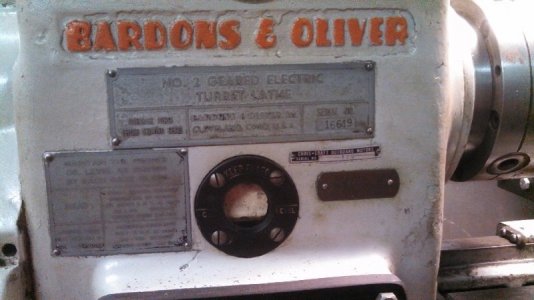

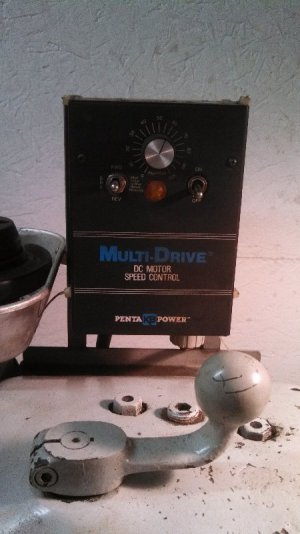

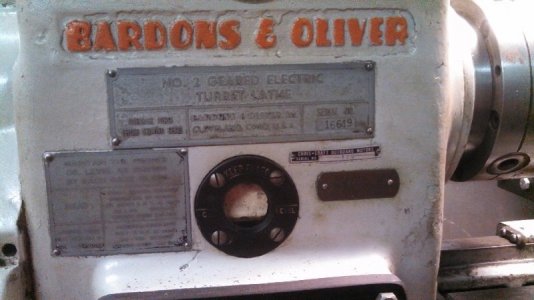

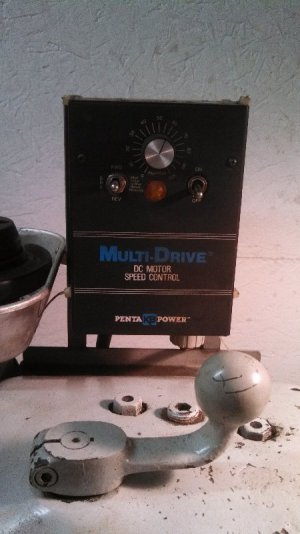

I have a Bardons & Oliver NO.2 geared turret lathe in my shop. I was thinking of getting rid of it to make some space for some other shop equipment. Years back I needed a lathe at the time, and ended up with it, doing some horse trading for some military truck parts. I've only used it for facing a few things since I had it all these years, and can't justify keeping it around. Because I'm not a machinist by trade, I have really no use for a turret lathe. I'm curious as what it might be worth? It came with a full set of collets, 3-jaw chuck, quick release chuck (don't know what it's actually called, but you can see it in laying in the upper pan) and it has also been converted to a (single-phase 220) variable drive, DC motor.

I welcome any input, thoughts or opinions....

I welcome any input, thoughts or opinions....