- Joined

- Apr 21, 2015

- Messages

- 589

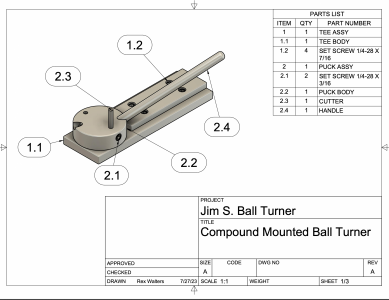

That turned out to be harder than you'd think, but I finally found the posts you meant.search this ball turner by Jimsehr. Jan 21 2022

For the record:

- Reply #36 showing the tool itself

- Reply #37: cutting radius in side/OD of a piece of stock

- Reply #39: turning a bowl into the end of a piece of stock (different tool)

Hemispherical radius cutter I made

Home made tool for cutting radius. https://photos.app.goo.gl/AtZUvTlcEwBGx8Y33

www.hobby-machinist.com

www.hobby-machinist.com

Note that I misunderstood Jim. He didn't split or turn back the puck, he just used a puck diameter smaller than the radius in the end of the part. The puck rides on a base that doesn't stick out as far, and the puck goes into the cavity of the bowl on the end. The maximum depth you can cut is the distance from the tip of the cutter to the left edge of the base (once it contacts the edge of the bowl, you're done). The radius of the arc is the distance from the tip of the cutter to the center of the puck.

Last edited: