- Joined

- Mar 10, 2020

- Messages

- 26

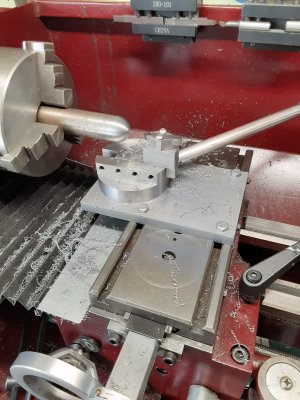

I am going to make my self a ball turner for my lathe. Not that i need one often, but, what can i say... a can't help myself....

I have Emco maximat super11 lathe, and my dilemma is which type to make, that classic with the turret, or the one that is called C type. Is there somebody more experienced that can write here pros and cons of each type?

I have Emco maximat super11 lathe, and my dilemma is which type to make, that classic with the turret, or the one that is called C type. Is there somebody more experienced that can write here pros and cons of each type?

![IMG_4117[1].jpg IMG_4117[1].jpg](https://www.hobby-machinist.com/data/attachments/341/341598-5d003daf30ac1fd0d18d8a47a672c44e.jpg)

![IMG_4118[1].jpg IMG_4118[1].jpg](https://www.hobby-machinist.com/data/attachments/341/341599-2a429cab7098f9bfcb263e113af27944.jpg)