- Joined

- Nov 22, 2010

- Messages

- 371

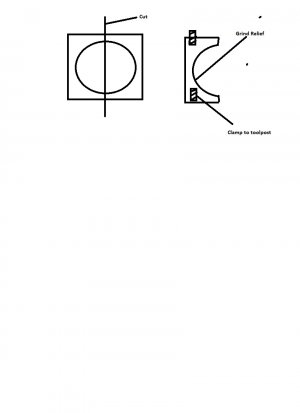

I am looking for a radius ball turning tool to use on my emco/maier compact 8 lathe to complete a project i am working on

I am a beginner at machining so un-able to take on building one from scratch so i am looking for perhaps one that i can modify to use on my lathe or perhaps a very simple desigh ( as opposed to Steve B's beautiful design but difficult for a beginner to construct me thinks )

)

I am a beginner at machining so un-able to take on building one from scratch so i am looking for perhaps one that i can modify to use on my lathe or perhaps a very simple desigh ( as opposed to Steve B's beautiful design but difficult for a beginner to construct me thinks