After a long hiatus, I’m trying to finish up my restoration (work has been ridiculous this year); It’s a Craftsman 12” 101.28991, serial number 001465.

Lo and behold- what do I find on the workbench as I’m finishing up? A spring and ball... of course.

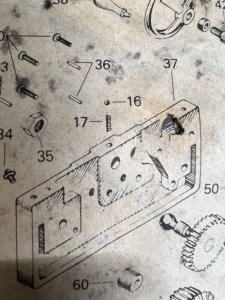

I’ve got my original, oily, tattered manual, so I start searching, and quickly found where the missing bits go. It’s for the cross feed engagement lever. BUT- here’s the problem- the ball doesn’t fit in the hole, and the length of the ball and spring are FAR too tall for the depth of the hole.

I searched the manual to see if I may have mixed up a ball/spring set. The only other two I found were in the back gear engagement lever, and half nut engagement mechanism. I removed both and they’re exactly the same ball and spring.

I got a slightly smaller BB to fit the hole, and tried to see if it’ll “work”, but once the spring gets tight against the carriage the cross feed lever is impossible to move.

So- did I miss/mix up a spring somewhere else?? I couldn’t find any others in my parts diagrams. Also, in my diagram, the ball is above the spring, which makes absolutely no sense.

Please advise!

Nooj

Lo and behold- what do I find on the workbench as I’m finishing up? A spring and ball... of course.

I’ve got my original, oily, tattered manual, so I start searching, and quickly found where the missing bits go. It’s for the cross feed engagement lever. BUT- here’s the problem- the ball doesn’t fit in the hole, and the length of the ball and spring are FAR too tall for the depth of the hole.

I searched the manual to see if I may have mixed up a ball/spring set. The only other two I found were in the back gear engagement lever, and half nut engagement mechanism. I removed both and they’re exactly the same ball and spring.

I got a slightly smaller BB to fit the hole, and tried to see if it’ll “work”, but once the spring gets tight against the carriage the cross feed lever is impossible to move.

So- did I miss/mix up a spring somewhere else?? I couldn’t find any others in my parts diagrams. Also, in my diagram, the ball is above the spring, which makes absolutely no sense.

Please advise!

Nooj