Texton Pilot bearing puller

That is a handy puller, I have one of those but it is only really used for pulling bearings out of blind holes where we can not get to the back of the bearing to push it out.

Either the Neiko or the OTC 4518 Set would be the best quality of the seperator puller sets and would serve you well.

The Texton 5704 looks like a set I used to have and I found the metal was poor quality, the seperator chipped and cracked at the jaws.

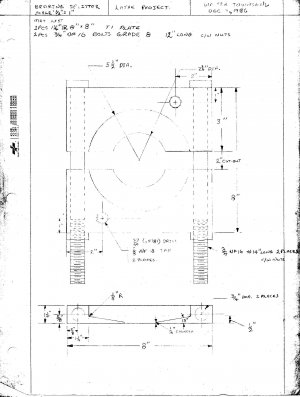

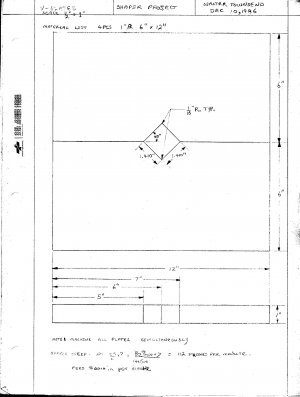

I am attaching the drawing of my plates and seperator if you want to attempt to make your own.

Now to press off the bearings, the rotor will hang between the table rails for the press, the seperator will be slid together under the bearing and the bearing will be on top of the seperator. Press down on the end of the shaft to remove the bearing.

To reinstall the bearing, plase the bearing on the plates, slide the shaft through and press on the other end of the shaft until the bearing is fully seated.

NB: make sure that everything is sitting square and that you are not pressing at an angle. I will start my press, release pressure then press again, this allows the shaft and bearing to equalize. If you press it off kilter, with 12 Tons, it will press on, but it will damage things in the process.

The big thing Nelson, is do the bearings on this grinder need replacing? Are they rough, and scratchy or what? You may find that they will run just fine without changing them.

Walter