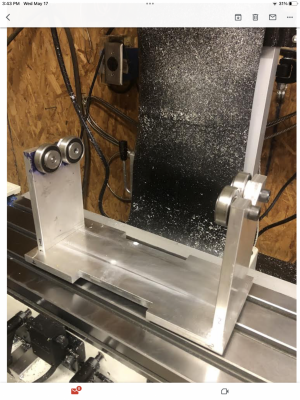

The 4 jaw chuck on PM 1236 out of box was so bad out of balance it was unusable above 200 rpm due to vibration. Cleaning casting debris from rear helped some. Cost of new balancer prohibited. Build a clone from material on hand. Tested at 800 rpm and ran smoothly without any vibration.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Balance 4-jaw chuck for PM 1236

- Thread starter Digger42

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,550

What happens when you chuck up a piece or work in your in your independent that isn't round or radially symmetrical?

- Joined

- Nov 27, 2012

- Messages

- 7,857

Yep my thought exactly. Sometimes there's no way around it depending on what you have chucked up but if the workpiece isn't extremely odd in shape/out of balance, I can usually find a spindle speed where the lathe doesn't shake that bad. Usually a slower rpm but sometimes faster. Variable speed would be nice but I don't have that, just the stock gearhead, same lathe as the OP. I no longer have the stock 4-jaw, mine is a direct mount no backplate. Less overhang which helps a bit I suppose.What happens when you chuck up a piece or work in your in your independent that isn't round or radially symmetrical?

- Joined

- Apr 23, 2018

- Messages

- 6,550

My chuck is always out of balance when I'm refreshing Sharpies.

Edit: You can tell I'm being facetious; my Sharpies don't go bad because they live in a mug, tips down.

Edit: You can tell I'm being facetious; my Sharpies don't go bad because they live in a mug, tips down.

- Joined

- Nov 27, 2012

- Messages

- 7,857

Haha! My Sharpies don't go bad either. I haven't used that thing since, it was really just a joke & was something to do cause I was bored.

I always have boxes of spare Sharpies anyway. And the Sharpies I use the most I use these holders. They have a magnetic base so I store them tip down or horizontally. One for the garage/shop, the other I keep in the house, mainly in my bedroom. Yeah, fancy smancy I know but I had to have em when I seen em. I'm over it now though, wish I had a 3D printer!

I always have boxes of spare Sharpies anyway. And the Sharpies I use the most I use these holders. They have a magnetic base so I store them tip down or horizontally. One for the garage/shop, the other I keep in the house, mainly in my bedroom. Yeah, fancy smancy I know but I had to have em when I seen em. I'm over it now though, wish I had a 3D printer!

- Joined

- Apr 23, 2018

- Messages

- 6,550

Nice holders! Might be fun to make a 6-shooter cylinder sharpie caddy. I will need to come up with multiple solutions, since Sharpie went on an injection molding bender a couple years ago. The amazing nitro solvent industrial sharpies are rectangular and come in 3 sizes, and now regular sharpie pen bodies are different from chisel tips, with multiple sizes there, too. And as soon as I get it worked out, they'll have to change their industrial designer and revamp the line again.

Have not tried, only round stock. Would expect it to work as any 4 jaw.What happens when you chuck up a piece or work in your in your independent that isn't round or radially symmetrical?

- Joined

- Apr 23, 2018

- Messages

- 6,550

I'm sorry, @Digger42, I should have tried to field your question a little more honestly before unpacking the sarcasm.Have not tried, only round stock. Would expect it to work as any 4 jaw.

I think balancing chucks is a good idea in general, if the factory didn't do a good job initially first. I skipped that step with the last half dozen chucks I bought, because secondary balancing by the end-user is a disqualifier on my personal quality agenda. If it were a three jaw scroll chuck, I would have saluted and said good work, carry on. But because it was a 4-jaw independent, and independent chucks are fundamentally imbalanced, I made the comment to see if you would pick up on that fact. I made it obvious by asking if it would work under a non-symmetric part. I could have also suggested an off-center part, since the 4-jaw is how you accomplish an eccentric hole, for example. This alludes to the usage of independent chucks for deliberate off-centering or for gripping nonuniform parts. Both of these conditions are inherently out of balance and off-axis.

So what I'm saying is, I narcissistically posted to see if you catch on, and if not, I started popcorn. I apologize for using you for my own entertainment. I probably owe a lot of people around here the same spiel.

- Joined

- Dec 18, 2022

- Messages

- 1,729

That is excellent, I have a similar issue. When you center up on a shaft with the jaws to hang the chuck in the balancer do you need to center something, like a spider, in the back of the chuck to hold the weight since the hiolding force of the jaws are out in front of the chuck?The 4 jaw chuck on PM 1236 out of box was so bad out of balance it was unusable above 200 rpm due to vibration. Cleaning casting debris from rear helped some. Cost of new balancer prohibited. Build a clone from material on hand. Tested at 800 rpm and ran smoothly without any vibration.