-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Automatic Screw Machines

- Thread starter NightWing

- Start date

B

Bill Gruby

Forum Guest

Register Today

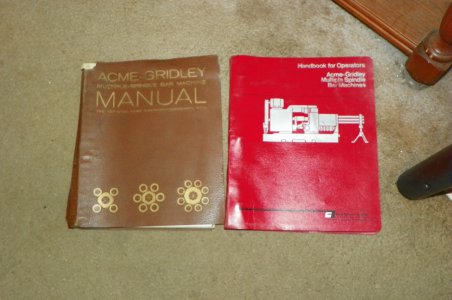

30 years worth. What would you like to know? Acme and New Britain. I still have the Acme Manual.

"Billy G"

"Billy G"

- Joined

- May 2, 2014

- Messages

- 217

30 years worth. What would you like to know? Acme and New Britain. I still have the Acme Manual.

"Billy G"

Actually, I was a field service engineer for 10 years on Conomatics and 8 more years as Service Manager. Then I had my own production shop using Cones for 22 years. I was just curious if anyone else here had ever run or worked on multis.

B

Bill Gruby

Forum Guest

Register Today

The 10 inch Acme was fun. :lmao::lmao: ! 5/8 - 8 triple cut offs were a nightmare. Then there was threading, oh yeah I remember those days. :lmao:

"Billy G"

"Billy G"

B

Bill Gruby

Forum Guest

Register Today

- Joined

- Nov 20, 2014

- Messages

- 670

we had a job we ran on an 1-5/8 rb 8 that we used to cut parts off one side, until we decided we could be cutting them off of both sides. I doubt they cut the price on them any but ill bet profits went up. two parts each machine cycle had to boost the profit margin!

B

Bill Gruby

Forum Guest

Register Today

Our R8s were triple cut offs. They made spacers from thin wall tubing. They had an expander tool to increase the OD and ID. Cycle time was 11 seconds. 8000+ in an 8 hour shift.

"Billy G"

"Billy G"