- Joined

- Jan 25, 2015

- Messages

- 2,558

The lock in my Atlas 10F tail stock has never really "locked". The locking lever will come tight, but the quill never seems to actually "lock".

It does seem like it will tighten the quill up a little bit, but the quill still moves side to side a bit and will sort of "pulse" in and out a bit as you are doing things like working a live center, drilling etc.

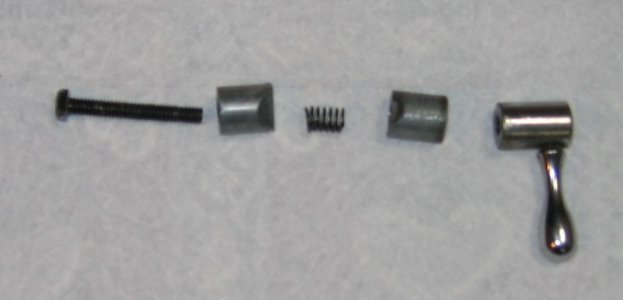

I've had the lock apart and it sure looks like several PO's have been in there and either re-shaped or re-ground the bevel on the locking pieces (which I believe is the problem). There's a least two seperate bevel profiles on it. So I don't even have an example to make new ones from.

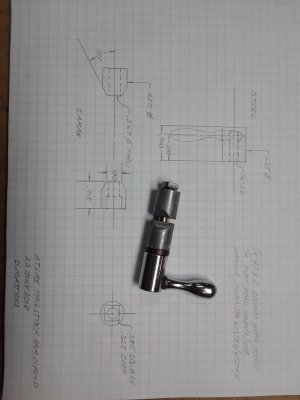

Anyone have pictures, measurements of an unmolested lock or perhaps an engineering drawing so I can make a set that at least functions as per?

It does seem like it will tighten the quill up a little bit, but the quill still moves side to side a bit and will sort of "pulse" in and out a bit as you are doing things like working a live center, drilling etc.

I've had the lock apart and it sure looks like several PO's have been in there and either re-shaped or re-ground the bevel on the locking pieces (which I believe is the problem). There's a least two seperate bevel profiles on it. So I don't even have an example to make new ones from.

Anyone have pictures, measurements of an unmolested lock or perhaps an engineering drawing so I can make a set that at least functions as per?

Last edited: